A triple offset butterfly valve is a type of industrial valve used for fluid control applications. It has an oblique sealing disc and three concentric seals, creating tighter seals and lower operating torque than other types of valves. The triple offset design also makes it easier to achieve low leakage rates and higher pressure ratings with smoother operation compared to conventional valves. This article will explore what a triple offset butterfly valve is, the benefits it offers, its components and operation, major applications, common challenges associated with the valve, and how it works.

Definition and Overview

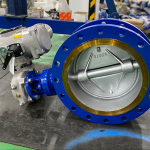

A triple offset valve is an industrial valve that is used for controlling the flow of liquids and gases. It has a unique design that consists of three rings, two in the center and one outside. Compared to other valve types, the triple offset butterfly valve has an oblique sealing disc and three concentric seals. This enables it to create tighter seals with lower operating torque than conventional valves.

In addition to its sealing capabilities, this type of butterfly valve also offers higher pressure ratings due to its smooth operation and low leakage rates. The triple offset design also makes it easier to install compared to other types of valves since fewer components are involved. Common applications include steam service, process control systems, chemical processing, and shipbuilding.

Benefits of Using a Triple Offset Butterfly Valve

A offset butterfly valve offers numerous advantages for various applications. Firstly, it provides higher pressure ratings and smoother operation compared to conventional valves due to its oblique sealing disc and three concentric seals. This enables it to create tighter seals with lower operating torque. Additionally, the triple offset design also makes it easier to install since fewer components are involved.

Furthermore, this type of valve is designed to handle larger volumes of flow with less wear on the seat-disc interface while also having a longer service life than other types of valves. It is also more cost effective due to its simple design and easy installation process. Last but not least, this type of valve has low emission rates due to its efficient flow control, making it an ideal candidate for applications requiring precise flow control such as steam service and process control systems.

Components and Operation

A butterfly valve consists of several components that work together to control the flow of fluids and gases. The primary component is the disc, which provides the actual sealing surface between the clamped-down seat or flange and the media running through it. Other components include a stem, body, packing gland, and mounting flanges.

The stem connects to an actuator which enables the user to open or close the valve by rotating it in either direction. During operation, when the stem is turned to open position, the disc moves away from its seated position allowing fluid or gas to pass through freely. Conversely, when it is rotated in a clockwise direction, it creates a tight seal that restricts flow making it ideal for regulating pressure and ensuring proper system control.

Major Applications

Triple offset butterfly valves have a wide range of applications, especially in industries where precise control of flow is required. They are commonly used for mid- or high-pressure operations, such as those found in steam systems and process plants. Additionally, they are also widely adopted in district heating and cooling systems, petrochemical plants, power generation plants and fluid transportation networks.

Furthermore, they can be used for fire protection systems when stringent safety requirements need to be met. Additionally, triple offset butterfly valves are also suitable for water treatment processes since they can provide effective leak tight shutoff with minimal pressure losses. Finally, these valves can also be used in wastewater systems as reliable isolation points without the risk of contamination or backflow.

Triple offset butterfly valve

In the realm of advanced valve technology, our Triple Offset Butterfly Valve stands as a paragon of design excellence and functional superiority. It incorporates a unique ‘triple offset’ design that ensures a bubble-tight, triple eccentric metal seal, creating an unrivaled solution for high-pressure and high-temperature applications.

The triple offset design is a testament to our engineering prowess, eliminating the friction between the disc and the seal during operation. This not only extends the valve’s lifespan but also facilitates zero-leakage performance.

Our Triple Offset Butterfly Valve features a metal-to-metal sealing system, offering enhanced durability and resilience. The metal seal, meticulously machined to exacting standards, provides superior sealing capabilities even under extreme operating conditions.

Adhering to the highest safety protocols, our valve is also fire-safe. In the event of a fire, the valve’s design enables it to maintain its seal integrity, preventing the uncontrolled release of fluids.

Common Challenges

Using a triple offset butterfly valve can present several common challenges. The most important challenge is achieving the correct sealing pressures and overall performance in the valve. High torque values are also a concern, as these valves must be able to perform under extreme conditions with no impact on their structural integrity. In addition, installation can be difficult since they require precise assembly and positioning of components to ensure proper operation.

As with any other valve system, there can be vibration-related problems that need to be addressed by installing vibration damping systems or modifying the design of the valve body. Additionally, ensuring maximum service life and minimal maintenance requirements is also a major challenge when working with triple offset butterfly valves.

Sealing Design

Triple offset butterfly valves have a unique sealing design which makes them suitable for a wide range of applications. The seat and seal arrangement of this type of valve ensures that it can provide a tight shutoff when the valve is in the closed position. This is due to the fact that the sealing elements are designed to conform exactly to the body contours, thus creating an effective and leak-proof contact between them.

Furthermore, there is also less wear and tear on the system since the torque needed to operate them is significantly lower than other types of valves. Additionally, these valves are also able to regulate flow up or down with minimal friction losses, providing additional efficiency benefits. Finally, they are often corrosion resistant due to their various materials choices, making them ideal for use in corrosive environments.

Advantages of the Specific Design

Double offset butterfly valve have several advantages due to their specific design. One of the main benefits is that they provide a high degree of accuracy in flow regulation, allowing users to precisely control the flow rate of fluids through them. Additionally, this type of valve also offers a low-pressure seal with minimal torque requirements for operation and excellent shutoff capabilities.

Furthermore, they are also extremely durable, able to withstand a wide range of temperatures and pressures without failure or leakage. Finally, these valves are generally easier to install than other types since they can be maneuvered into tight spots without the need for additional supports or brackets. All of these factors make triple offset butterfly valves an attractive option for many applications.

Pressure Rating and Other Factors Affecting its Performance

Triple offset butterfly valves are rated for a certain pressure, which is determined by the material and design of the valve. Additionally, other factors such as the type of fluid being used, the temperature and pressure of the system, as well as environmental conditions such as chemical corrosion or abrasion can all affect the performance of these valves.

Similarly, incorrect installation or maintenance can also lead to reduced performance and even potential failure of the valve. It is therefore important that these valves are installed and maintained properly in order to ensure they will perform optimally in any given application. Furthermore, it is always advisable to consult with an expert in order to determine what kind of rating is required for any specific application.

Installation Requirements

The installation of triple offset butterfly valve generally requires careful attention to detail in order to ensure that they are installed correctly and securely. One important step is ensuring the piping system has been properly aligned prior to installing the valve, as misalignment can create pressure and turbulence that may cause leaks or damage the valve.

Additionally, valves should be secured with bolts and nuts that are both rated for the correct pressure and torque setting in order to guarantee a secure fit. It is also important to select piping materials that are compatible with the type of material used for the valve itself. Finally, it is advisable to confirm with local codes and regulations regarding any specific requirements for installation.

Maintenance Strategies

Maintenance strategies for triple offset butterfly valves must be tailored to the specific application, with careful attention paid to any changing environmental conditions. It is important to monitor the system for signs of wear and damage, such as vibration or noise coming from the valve, which can indicate a potential fault. Additionally, regular inspections should be carried out in order to ensure that all parts are in good condition and free from corrosion or any other forms of damage.

If necessary, any damaged parts must be replaced promptly or the entire valve may need to be disassembled and re-assembled. Regular lubrication is also necessary in order to keep the seals healthy and prevent wear on moving parts. Finally, it is essential that all safety systems are regularly tested in order to ensure they are functioning properly.

-150x150.jpg)