Butterfly check valves are a type of valve used in piping systems and industrial applications that provide reliable flow control with a wide range of advantages over other types of valves. From durability and reliability to cost efficiency and easy maintenance requirements, butterfly check valves are an optimal choice for any application. Additionally, their space-saving design makes them ideal for tight spaces where other valves may not fit. By taking all the advantages into consideration when making a purchase decision, you can ensure you get the best valve for your needs.

Introduction

Butterfly check valves offer many advantages over other types of valves, such as durability and reliability. This type of valve is designed with a flap or disc that opens or closes in response to pressure changes in the flow line, making them excellent for controlling flow. They are also resistant to corrosion and rust, allowing them to withstand harsh conditions without requiring frequent repairs. In addition, they have low maintenance requirements, meaning fewer costs associated with upkeep. Furthermore, their space-saving design makes them ideal for tight spaces where other valves may not fit. Finally, thanks to their cost-efficient nature, butterfly check valves are an economical choice for most applications. All these advantages combine to make butterfly check valves an optimal choice for any application requiring reliable flow control with minimal maintenance requirements.

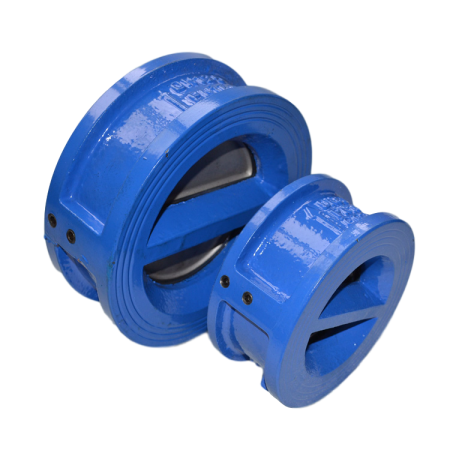

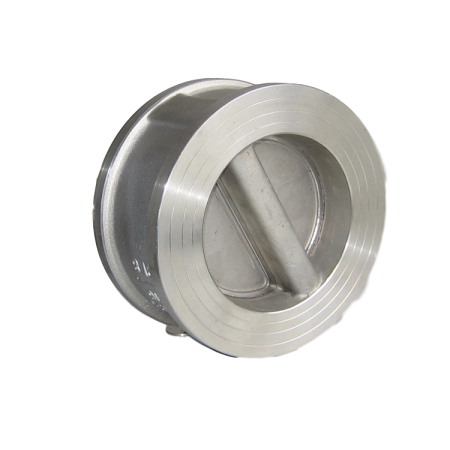

Definition of butterfly check valve

A check valve, also known as a swing check valve, is a type of valve used to prevent reverse flow in a pipeline. The valve works by allowing flow in one direction while blocking it in the reverse direction. It consists of a disc that swings on a hinge and rests against a seat when the flow stops, preventing backflow. Butterfly check valves are commonly used in a variety of industries, including water treatment, chemical processing, and food and beverage production. They are often favored for their simple design, reliable performance, and low maintenance requirements.

Overview of different types of valves

Valves are devices that control the flow of fluids in a pipeline or system. There are numerous types of valves, each with its own specific features, applications, and advantages. Gate valves, for instance, are often used to control the flow of large quantities of fluids, while globe valves are commonly used in applications that require precise flow control. Ball valves, on the other hand, offer quick and reliable shutoff, while check valves prevent reverse flow. Diaphragm valves are ideal for use with abrasive or corrosive fluids, while butterfly valves are favored for their simple design and low maintenance requirements. Other types of valves include needle valves, pinch valves, pressure relief valves, and solenoid valves. Each type of valve has its own unique capabilities and benefits, making them suitable for specific applications in a variety of industries, from chemical processing to oil and gas production.

Comparison of Butterfly Check Valve to Other Types of Valves

Butterfly check valves are a type of valve that operate in a similar fashion to other types of check valves, such as swing check valves and lift check valves. However, butterfly check valves have a unique design that makes them well-suited for certain applications. Compared to gate valves, butterfly check valves offer faster opening and closing times and require less space in the pipeline. This makes them a popular choice in industries that require frequent start-stop cycles or have limited space for valve installation. They are also lighter and more compact than other types of valves, which makes them easier to install and maintain.

When compared to globe valves, butterfly check valves offer a simpler design and lower cost, which makes them ideal in low-pressure applications. Globe valves, while more expensive than butterfly check valves, provide precise flow control and are less prone to leaking.

Ball valves operate similarly to butterfly check valves, with a quick opening and closing mechanism, but they are better suited for high-pressure applications. Ball valves provide more precise flow control at higher pressures, but they are also more expensive and have higher maintenance requirements.

Overall, butterfly check valves are a reliable and cost-effective solution for many industries. They are simple to operate, require minimal maintenance, and can be installed in tight spaces. While they may not be suitable for all applications, they are an excellent choice for industries that demand efficiency and affordability.

Durability and Reliability

Durability and reliability are important considerations when it comes to valves. A valve that is not durable or reliable can cause significant disruptions to a system or pipeline, leading to wasted time and money. Butterfly check valves are known for their durability and reliability, making them a popular choice in many industries. They are designed to withstand high-pressure and high-temperature environments, ensuring that they won’t fail or leak over time. Additionally, butterfly check valves have a simple design with fewer moving parts, meaning that they are less prone to wear and tear. This translates to lower maintenance costs and longer service life. Overall, butterfly check valves offer an ideal balance of durability and reliability that makes them a valuable asset to any pipeline or system.

Pressure Ratings and Flow Dynamics

Butterfly check valves are designed to handle a wide range of pressure ratings and flow dynamics. They are typically rated for both minimum and maximum pressure ratings, which helps ensure that they perform optimally within their intended range. Butterfly check valves can be found in low-pressure systems, such as irrigation or waste water, as well as high-pressure systems, such as oil and gas pipelines. When it comes to flow dynamics, butterfly check valves are well-suited for both laminar and turbulent flow, thanks to their streamlined design. This means that they can efficiently regulate flow in a variety of applications, from high-velocity water treatment systems to low-velocity chemical processing plants. Overall, butterfly check valves offer exceptional versatility when it comes to pressure ratings and flow dynamics, making them an ideal solution for a broad range of industrial applications.

Space Saver Design

The space-saving design of swing check valve is one of their main advantages. Unlike other valve types that require a lot of space for installation and operation, butterfly check valves have a compact and streamlined design. They can be installed in tight spaces, making them ideal for applications where space is limited. Because of their design, butterfly check valves can be included in a piping system with minimal additional supports or restraints. This can lead to significant cost savings in terms of both materials and labor. Additionally, butterfly check valves require less maintenance than other valve types, which means less downtime and reduced labor costs. Overall, the space-saving design of butterfly check valves is a significant benefit that makes them a popular choice in many industries.

Repair Advantages

Butterfly check valves offer several advantages when it comes to repairs. Because of their simple design with fewer moving parts, butterfly check valves are easier and less costly to repair than other valve types. Replacing parts is also simple and doesn’t require extensive knowledge or experience. Butterfly check valves usually have a two-piece body design that simplifies maintenance procedures, while the valve seat can be easily removed and replaced when damaged. Furthermore, butterfly check valves do not require additional gaskets, reducing the risk of leakages during disassembly and reassembly. This ease of repair and maintenance translates to less downtime and reduced maintenance costs, making butterfly check valves an ideal choice for industries that require reliable, low-cost solutions.

Cost Efficiency Advantages

Cost efficiency is another significant advantage of butterfly check valves. Compared to other valve types, butterfly check valves are generally more affordable due to their simpler design with fewer components. They can be manufactured using lower-cost materials without compromising quality or durability, which helps to keep costs down. Additionally, butterfly check valves require less maintenance and repairs over their lifetime, leading to further cost savings. They are also lightweight and compact, making transportation and installation more cost-effective. The cost efficiency of butterfly check valves makes them an ideal choice for industries that require reliable and cost-effective solutions, such as wastewater treatment, chemical processing, and mining. Overall, the affordability and reduced maintenance costs of butterfly check valves make them a popular choice for many industrial applications.

Reduced Maintenance Requirements

Reduced maintenance requirements are a key advantage of double check valve . Their simple design with fewer moving parts means that butterfly check valves are less prone to wear and tear and require less maintenance than other valve types. They are less likely to leak or fail, leading to less downtime and reduced maintenance costs. Butterfly check valves also require fewer replacement parts than other valves, which leads to less clutter and saves on inventory costs. Butterfly check valves have fewer crevices and cavities, which reduces the buildup of sediment and debris. This feature not only reduces the risk of blockages and corrosion, but it also minimizes the likelihood of contamination from stale fluids. Overall, reduced maintenance requirements make butterfly check valves a cost-effective and reliable option for industries that need a low-maintenance solution.

Conclusion

By considering all these points, you can easily choose the best valve for your needs and ensure maximum efficiency in your piping system or industrial application. Butterfly check valves have many advantages over other types of valves, from durability and reliability to cost efficiency and the space-saving design. They are an optimal choice for any application that requires reliable flow control with minimal maintenance requirements. Additionally, butterfly check valves can be easily repaired or replaced if necessary. By carefully considering all the advantages when making a purchasing decision, you can ensure a perfect fit for your application that meets all of your needs.