In the world of industrial applications, butterfly valve play a pivotal role in controlling the flow of liquids or gases through pipes. Predominantly, there are two types of butterfly valve: manual and air actuated. Both have their unique set of advantages and trade-offs, but the choice between the two often depends on the specific industry and its requirements. In this article, we delve deep into the comparison between manual and air actuated butterfly valve from a South African perspective. We’ll explore their functionality, cost-effectiveness, durability, and suitability for different industrial sectors within the South African landscape. The aim is to provide a comprehensive understanding that can guide industries in making informed decisions about their valve selection.

Introduction

In South Africa, the choice between manual and air actuated butterfly valve is primarily driven by the specific needs of different industries. Manual butterfly valve are simple in design, easy to install and operate, and require no external power source. They function by using a hand wheel or lever to open, close, or regulate the flow of fluid. This makes them an economical choice for small-scale industries or systems where precise control is not paramount. For instance, they are commonly used in water distribution networks, agricultural irrigation systems, and small-scale manufacturing units in South Africa. However, their simplicity also has its downsides. Manual butterfly valve demand physical effort to operate and may not be suitable for remote operations or large-scale industrial applications.

On the other hand, air actuated butterfly valve offer advanced functionality and automation. They use compressed air to actuate the valve, enabling quick and efficient opening and closing. Air actuated butterfly valve are ideal for large-scale industrial processes that require high-speed operation, precise flow control, and minimal human intervention. For instance, they are widely used in South Africa’s mining, power generation, and petrochemical industries. The ability to operate remotely and integrate with automated systems makes air actuated butterfly valve a preferred choice for modern, technologically advanced industries. However, they come with a higher initial cost and require a consistent supply of compressed air, which can increase operational expenses over time.

Ultimately, the choice between manual and air actuated butterfly valve in South Africa depends on the specific requirements of the industry, budget constraints, and the nature of the application. It’s crucial for industries to carefully evaluate these factors before making a decision, as the right valve can significantly enhance operational efficiency and reliability.

Brief explanation on what butterfly valve are and their importance in various industrial applications.

Butterfly valve are a type of flow control device widely used in various industrial applications. They consist of a disc mounted on a rotating shaft inside a pipe, which regulates the flow of fluid (gas or liquid) passing through it. When the disc is turned parallel to the flow, the valve is fully open, and when it’s turned perpendicular, the valve is closed, thus controlling the rate of flow. The simplicity of their design makes them cost-effective and easy to maintain. Butterfly valve are crucial in industries like water and wastewater treatment, oil and gas, power generation, and chemical processing due to their ability to handle large flow rates efficiently. They also excel in applications that require the ability to isolate or throttle the flow, making them an integral part of many industrial processes. The importance of butterfly valve lies in their versatility, durability, and the pivotal role they play in ensuring operational efficiency in various industries.

Overview of the discussion: Comparing manual and pneumatic butterfly valve from a South African perspective.

In this discussion, we delve into an in-depth comparison of manual and air actuated butterfly valve from a South African perspective. We explore the functionalities, cost implications, durability, and application suitability of each type of valve within the diverse industrial landscape of South Africa. Manual butterfly valve, known for their simplicity and affordability, are commonly used in small-scale industries or systems where precision is not a crucial factor. However, their requirement for physical operation can be a limitation. On the flip side, air actuated butterfly valve offer advanced automation and efficiency, making them ideal for large-scale, technologically advanced industries that require high-speed operation and precise control. However, they come with a higher initial cost and require a consistent supply of compressed air. By understanding these nuances, industries can make an informed decision that best suits their operational needs and budget constraints.

Understanding Butterfly Valve

Butterfly valves are a unique type of industrial valve known for their simple yet effective design and diverse utility. They consist of a disc attached to a rotating shaft, positioned within a pipe or tube, which controls the flow of fluids – be it gas or liquid. The name ‘butterfly’ comes from the disc’s resemblance to butterfly wings when viewed from the top. The operation of these valves is straightforward; when the disc is aligned parallel to the flow, the valve is in the open position, allowing fluid to pass through. Conversely, when the disc is turned to a position perpendicular to the flow, the valve is closed, effectively blocking the passage of fluid.

The butterfly valve’s key advantages include its lightweight design, cost-effectiveness, and ease of installation and maintenance. Furthermore, they can handle large flow rates efficiently, making them incredibly valuable in numerous industrial applications. Industries such as water and wastewater treatment, oil and gas, power generation, and chemical processing frequently utilize butterfly valves due to their ability to isolate or throttle the flow of fluids swiftly and effectively.

Despite their simplicity, butterfly valves come in several variations, including resilient seated, high-performance, and triple offset types, each offering specific benefits for different operating conditions. For instance, resilient seated butterfly valves are ideal for low-pressure scenarios, while high-performance and triple offset butterfly valves are designed to withstand higher pressures and temperatures.

In essence, understanding butterfly valves is crucial as they play an integral role in ensuring operational efficiency across various industries. Their versatility, durability, and ability to control fluid flow under different conditions make them an indispensable element in many industrial processes.

Detailed description of butterfly valve, their design and functionality.

Butterfly valves are specially designed flow control devices that are widely utilized in various industrial applications. The primary components of a butterfly valve include a disc, a stem, and a seal (or seat). The disc, often circular or slightly oblong, is the heart of the valve, acting as the blockade to control the fluid flow. It’s attached to the stem, which runs through the center of the disc at a right angle. When the stem is turned, the disc rotates, opening or closing the valve.

In terms of functionality, butterfly valves operate on a simple principle. When the disc is rotated to align parallel with the fluid flow, the valve is open and fluid can pass through unobstructed. Conversely, when the disc is rotated to a position perpendicular to the flow, the valve is closed, blocking fluid passage. This operation can be manual, using a handle, or automated, using actuators.

The seal or seat of the valve plays a critical role in ensuring a tight closure when the valve is in the closed position. Depending on the specific design of the butterfly valve, the seal can be mounted on the body of the valve or on the edge of the disc.

The design and functionality of butterfly valves make them highly versatile, capable of handling different types of fluids (gases, liquids) across a wide range of pressures and temperatures. Their compact size, lightweight, ease of installation and maintenance, and cost-effectiveness further contribute to their widespread use in industries such as water treatment, oil and gas, chemical processing, and power generation.

Explanation of the two types of butterfly valve: manual and air actuated.

Butterfly valves, known for their simplicity and versatility, come in two primary types: manual and air actuated. Manual butterfly valves are operated by a handle or wheel that needs to be manually turned to open or close the valve. They’re simple, cost-effective, and easy to operate, making them a suitable choice for small-scale operations or systems where precise control isn’t critical. However, they do require physical effort, and their operation can be time-consuming, especially in larger systems.

On the other hand, air actuated butterfly valves use pneumatic power to operate. They are equipped with an actuator – a device that converts energy into motion – which uses compressed air to open or close the valve. This type of butterfly valve offers higher speed, efficiency, and precision compared to their manual counterparts. They are ideal for large-scale industrial applications where swift and accurate control of fluid flow is necessary. However, air actuated butterfly valves have a higher initial cost and require a consistent supply of compressed air to function. Understanding these differences can help industries select the appropriate type of butterfly valve that best meets their operational requirements and budgetary constraints.

Importance of butterfly valve in South Africa’s industrial sector.

In South Africa’s industrial sector, butterfly valves play a pivotal role in ensuring the efficient and effective management of fluid flow. Given the country’s vast mining, oil and gas, and power generation industries, along with its growing water and wastewater treatment facilities, the demand for reliable and durable flow control solutions is high. Butterfly valves, with their simple design, cost-effectiveness, and versatility, meet these requirements aptly. They allow for swift isolation or regulation of flow, contributing to enhanced operational efficiency and safety. The compact size and lightweight nature of butterfly valves make them easy to install and maintain, which is particularly beneficial in the context of South Africa’s expansive industrial operations. Moreover, the availability of different types of butterfly valves – manual, air actuated, resilient seated, high-performance, and triple offset – allows for their use in a wide range of applications, from low-pressure scenarios to high-temperature conditions. Thus, the importance of butterfly valves in South Africa’s industrial sector cannot be understated, as they are integral to the smooth and safe functioning of numerous industrial processes.

Manual Butterfly Valve

Manual butterfly valves are a type of quarter-turn valve that regulates the flow of a fluid. They are named for their distinctive design, which features a disc mounted on a rotating shaft, resembling a butterfly’s wings in mid-flight. The operation of manual butterfly valves is quite straightforward: when the handle or wheel is turned by hand, the disc turns on the shaft, either parallel or perpendicular to the flow of fluid. When the disc is parallel, the valve is fully open and allows unimpeded flow; when it’s perpendicular, the valve is fully closed, blocking all flow.

The simplicity of this operation is one of the main advantages of manual butterfly valves. They are easy to use, even for non-technical personnel, and require no additional power source, making them a reliable option in remote or resource-limited settings. Moreover, due to their compact and lightweight design, manual butterfly valves require less space compared to other types of valves and are easier to install and maintain. This makes them a cost-effective solution for many industrial applications, from water and wastewater treatment to oil and gas, chemical processing, and food and beverage production.

Despite their simplicity, manual butterfly valves can handle a wide range of pressures and temperatures, depending on the material used for the disc and the seal (or seat). Common materials include stainless steel, cast iron, and plastic for the disc, and elastomers like EPDM or NBR for the seal. Some manual butterfly valves also feature a locking mechanism on the handle, allowing for secure positioning at various degrees of openness for more precise flow control.

However, manual butterfly valves are not without their limitations. They require physical effort to operate, which can be challenging in large-scale systems or for valves with high pressure drops. They also lack the speed and automation capabilities of actuated butterfly valves, making them less suitable for applications requiring rapid or frequent operation. Despite these challenges, manual butterfly valves remain a popular choice due to their overall reliability, versatility, and cost-effectiveness.

In-depth explanation of manual butterfly valve: how they work, their advantages and disadvantages.

Manual butterfly valves are a common type of flow control device used in various industrial applications. They function by using a disc, which is mounted on a rotating shaft within the valve’s body. When the hand-operated lever or wheel is turned, it rotates the disc either perpendicular or parallel to the fluid flow. When the disc aligns parallel with the flow, the valve is in the open position allowing unrestricted fluid passage. Conversely, when the disc is positioned perpendicular to the flow, the valve is closed, halting the fluid flow completely.

One of the primary advantages of manual butterfly valves is their simplicity and ease of operation. They require no additional power source, making them convenient for use in remote locations or in scenarios where power availability is an issue. Furthermore, they are typically more compact and lighter than other types of valves, making them easier to install and handle, particularly in space-constrained environments.

Despite these advantages, manual butterfly valves also have some disadvantages. They require physical effort to operate, which can become strenuous, especially in large-scale systems or in situations with high pressure drops. They lack the automation capabilities of actuated valves, making them less suitable for applications that require frequent or rapid opening and closing of the valve. Manual butterfly valves also may not provide the same level of precise control as other valve types, which can be a limiting factor in certain applications where precision is required. Nevertheless, for many operations, the manual butterfly valve remains a reliable and cost-effective choice.

Case studies or examples of industrial sectors in South Africa that predominantly use manual butterfly valve.

Manual butterfly valves are a crucial component in various industrial sectors in South Africa, contributing to the smooth operation of numerous processes. For instance, the country’s mining industry, a significant part of its economy, relies on these valves for effective flow control in various applications, such as bottom outlet dams. Another sector that extensively uses manual butterfly valves is the petrochemical industry. These valves are instrumental in managing the flow of various chemicals and gases, ensuring operational safety and efficiency. The water and wastewater industries are other notable users of butterfly valves. They aid in managing the flow of water and treatment processes, contributing to the sector’s sustainability efforts. Moreover, in the steelworks industry, these valves play a vital role in cooling systems, hydraulic systems, and more. Lastly, in the context of HVAC applications, butterfly valves are commonly used as isolation valves, providing reliable and efficient flow control. Therefore, manual butterfly valves, with their simplicity, cost-effectiveness, and versatility, are integral to several industrial sectors in South Africa.

Expert opinions on the use of manual butterfly valve in South Africa.

Experts in the field of industrial engineering and fluid control systems often highlight the significant role manual butterfly valves play in South Africa’s various industrial sectors. They point out that these valves’ simplicity, cost-effectiveness, and versatility make them a preferred choice for many applications, particularly in industries where a reliable and easy-to-operate flow control solution is required. For instance, in the mining sector, experts note that the toughness and durability of these valves are well-suited for the harsh environments typically encountered. In the water and wastewater industries, professionals emphasize the importance of these valves in managing flow and treatment processes, contributing to sustainability efforts. However, some experts also caution about the limitations of manual butterfly valves, such as their lack of automation capabilities and the physical effort required for operation, suggesting that other types of valves or automated solutions might be more suitable for certain applications. Despite these potential drawbacks, the consensus among many experts is that manual butterfly valves remain a vital component in South Africa’s industrial landscape.

Air Actuated Butterfly Valves

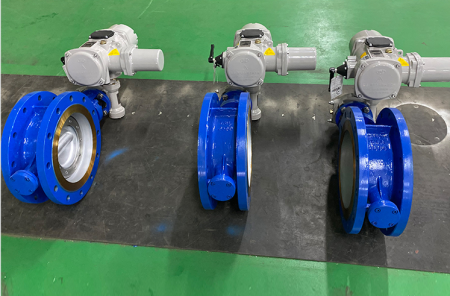

Air actuated butterfly valves are a type of valve that utilizes pneumatic power to control the flow of fluid within a pipe or tube. These valves consist of a disc mounted on a rotating shaft, similar to manual butterfly valves, but they differ in their mode of operation. Instead of a hand-operated wheel or lever, air actuated butterfly valves use pressurized air supplied by an external source to rotate the disc and open or close the valve.

When the valve receives a signal from the control system, the pneumatic actuator introduces pressurized air which causes the disc to rotate either to a fully open or fully closed position, depending on the design and requirement of the system. The use of air as a power source offers several advantages. The speed and force of the actuation can be easily adjusted by regulating the air pressure, allowing for precise control over the flow rate. This makes air actuated butterfly valves ideal for applications where rapid or frequent changes in flow are required.

Furthermore, these valves are inherently safe to operate as they don’t require electricity, making them suitable for environments where there’s a risk of explosion or fire. They are also capable of handling large flow rates, making them a popular choice for industrial applications, such as water treatment plants, chemical processing facilities, and HVAC systems.

Despite these advantages, air actuated butterfly valves do have some limitations. They require a continuous supply of clean, dry air to function properly, which may not be readily available in all settings. Moreover, they are typically more complex and expensive than manual butterfly valves due to the additional components and infrastructure needed for the pneumatic system. Nonetheless, the benefits of air actuated butterfly valves often outweigh these drawbacks in many applications, making them a valuable tool in flow control systems.

Detailed description of air actuated butterfly valves: their operation mechanism, benefits and potential drawbacks.

Air actuated butterfly valves are highly efficient flow control devices that operate using pneumatic power. Their operation mechanism involves a disc mounted on a rotating shaft within the valve’s body. When actuated by an external control system, pressurized air is introduced into the pneumatic actuator which causes the disc to rotate. Depending on the design and requirement of the system, the disc rotates to a fully open or fully closed position, controlling the flow of fluid within the pipe or tube.

The benefits of air actuated butterfly valves are numerous. They offer precise and rapid control over the flow rate by adjusting the air pressure, making them ideal for applications requiring frequent changes in flow. Being powered by air, they eliminate the need for electricity, enhancing safety in environments where there’s a risk of explosion or fire. These valves are also capable of handling large flow rates, which makes them popular in industrial applications like water treatment plants, chemical processing facilities, and HVAC systems.

However, air actuated butterfly valves do have potential drawbacks. They require a continuous supply of clean, dry air to function properly, which might not be readily available in all settings. Additionally, compared to manual butterfly valves, they tend to be more complex and expensive due to the additional components and infrastructure needed for the pneumatic system. These factors should be considered when deciding whether air actuated butterfly valves are the most suitable choice for a specific application.

Instances of industries in South Africa where pneumatic actuated butterfly valve are commonly used.

Air actuated butterfly valves have found wide applications in various industries within South Africa. One of the prominent sectors where these valves are commonly used is the water and wastewater industry, where they manage flow and treatment processes effectively. The automotive and textile industries also frequently utilize air actuated butterfly valves for different applications, contributing to their operational efficiency.

Moreover, the biogas, steelworks, chemical, and petrochemical sectors have been noted for their use of these versatile valves. In the realm of petrochemicals, chemicals, and oil industries, where safety and precise flow control are paramount, these valves have proven to be invaluable. Other industries, such as paper, coal mining, and medical treatment sectors, also make use of these valves, particularly pneumatic ones, for various functions.

Overall, the wide-ranging use of air actuated butterfly valves across multiple industries in South Africa underscores their versatility and functionality in managing flow control in diverse environments.

Expert views on the implementation of air actuated butterfly valve in South Africa.

Experts in the field of flow control and valve technology have expressed positive views on the implementation of air actuated butterfly valves in South Africa. They highlight that these valves, with their quarter-turn flow control or isolation capabilities, offer quick shut-off in piping systems, which is highly beneficial for various industrial applications. The flexibility in actuation methods, including manual, electric, pneumatic, and hydraulic, makes these valves highly adaptable for different operational needs.

Furthermore, experts point out that air actuated butterfly valves are particularly suitable for HVAC applications, given their design and functionality. Their robust and high-performance nature ensures they can effectively control media compatible with the materials of construction. Lastly, experts note that the use of electric valve actuators, which can control the opening and closing of valves, further enhances the efficiency and precision of butterfly valves.

The expert insights underscore the significant utility of air actuated butterfly valves in South Africa’s industrial landscape, particularly in sectors where precise and efficient flow control is essential.

Comparison: Manual vs Air Actuated Butterfly Valves

Manual and air actuated butterfly valve both serve the purpose of controlling fluid flow in a system, but they differ in their operation mechanisms, efficiency, and suitability for various applications. Manual butterfly valves are operated by physically turning a handle or wheel to open or close the valve. This manual operation provides easy control and is often suitable for smaller systems or environments where there’s no need for frequent adjustments. These valves are relatively simple, less expensive, and require no external power source which makes them ideal for remote locations or facilities with limited resources.

On the other hand, air actuated butterfly valves utilize pneumatic power to automate the process of opening and closing the valve. The introduction of pressurized air into a pneumatic actuator results in the rotation of the disc, thus controlling the flow of fluid. These valves offer rapid response times and precise control over the flow rate, making them ideal for applications requiring frequent changes in flow. They also eliminate the need for manual labor, enhancing efficiency and safety, especially in large-scale industrial settings where valves might be located in hard-to-reach areas. Moreover, being powered by air, they reduce the risk of explosion or fire in environments where electricity might pose a hazard.

However, air actuated butterfly valves have some potential drawbacks. They require a continuous supply of clean, dry air to function properly, which might not be readily available in all settings. Additionally, they tend to be more complex and costly due to the additional components and infrastructure required for the pneumatic system. In contrast, manual butterfly valves, while less sophisticated, are not dependent on an external power source and can offer reliable performance in a wide range of settings.

In conclusion, the choice between manual and air actuated butterfly valves largely depends on the specific requirements of the application, including factors like the frequency of valve operation, availability of power sources, budget constraints, and the need for precision control.

Comparative analysis of manual and air actuated butterfly valve based on cost, efficiency, durability, maintenance, etc.

Manual and air actuated butterfly valves each have their unique advantages and considerations when it comes to cost, efficiency, durability, and maintenance.

Starting with cost, manual butterfly valves are generally less expensive due to their simpler design and lack of need for an external power source. Air actuated butterfly valves, on the other hand, have additional components like a pneumatic actuator and control system, making them more costly initially.

In terms of efficiency, air actuated butterfly valves offer superior performance. They can be controlled remotely, respond quickly to changes, and provide precise control over flow rates. This makes them ideal for large-scale industrial applications or settings where frequent adjustments are necessary. Manual butterfly valves, while reliable, require physical effort to operate and may not be as efficient in scenarios requiring rapid or frequent adjustments.

When considering durability, both types of valves can offer long service lives if properly maintained. However, the durability of air actuated butterfly valves can be influenced by the quality of the air supply. Contaminants in the air can potentially damage the pneumatic actuator over time.

As for maintenance, manual butterfly valves typically require less upkeep due to their simpler design. Regular inspection and lubrication of the moving parts is usually sufficient. Air actuated butterfly valves, however, require more meticulous maintenance. The pneumatic system needs to be kept clean and dry, and the actuator and control system require regular checks to ensure optimal operation.

In summary, while manual butterfly valves may be more cost-effective and easier to maintain, air actuated butterfly valves offer superior efficiency and precision control, making them a worthwhile investment for certain applications.

Discussion on the suitability of each type of valve for different industrial applications in South Africa.

The suitability of manual and air actuated butterfly valves for different industrial applications in South Africa largely depends on the specific requirements of each application. Manual butterfly valves, with their simple operation and cost-effectiveness, are suitable for smaller systems or environments where there’s no need for frequent adjustments. They can be used in water treatment plants, irrigation systems, and certain sectors of the manufacturing industry where manual control over the flow of fluids is sufficient.

Air actuated butterfly valves, on the other hand, offer automated control, quicker response times, and more precise regulation of flow rates. These features make them ideal for large-scale industrial applications including mining, chemical processing, and power generation. In sectors like these, where safety and efficiency are paramount, the remote operation and rapid shut-off capabilities of air actuated valves are highly beneficial. Also, in South Africa’s burgeoning renewable energy sector, especially in wind and solar power plants, air actuated butterfly valves can play a crucial role in regulating fluid flows with high precision.

However, it’s important to note that the implementation of air actuated butterfly valves requires a reliable supply of clean, dry air, which may be a challenge in some remote or resource-constrained settings. Thus, the choice between manual and air actuated butterfly valves should consider factors like operational needs, available resources, and the specific demands of the industrial application.

Insights from industry experts on the choice between manual and air actuated butterfly valves.

Industry experts provide valuable insights on the choice between manual and air actuated butterfly valves. According to Pov Butterfly Valve, manual butterfly valves, either lever or gear-operated, are generally more cost-effective upfront due to their simpler design. Pumps and Systems highlight that butterfly valves’ lightweight design and quick operation make them suitable for various applications. Valveman emphasizes that actuated butterfly valves, with their compact and lightweight design, are used for quick shut-off in piping systems and can significantly improve flow coefficient. Experts at Chemical Processing advise that automatic actuation is a preferable choice when there’s a need to operate the valve remotely. Valmet discusses the benefits of a modular butterfly valve platform, suggesting the adaptability of these systems across a variety of industries. Valve Magazine notes that butterfly valves can be assembled with handles, manual gears, or pneumatic or hydraulic actuation, underscoring their versatility. Finally, US Duct points out that butterfly valves, both manual and automatic, are designed to assist with airflow rate changes, indicating their importance in HVAC systems.

The South African Perspective

The South African perspective is a unique blend of diverse cultures, rich history, and an evolving socio-political landscape. It’s shaped by the country’s past of apartheid, the subsequent struggle for equality, and the ongoing challenges in achieving social justice and economic stability. As one of Africa’s most developed economies, South Africa plays an influential role on the continent. Its industries, from mining and manufacturing to services and information technology, contribute significantly to its GDP. However, the country also grapples with issues like income inequality, unemployment, and poverty.

The South African perspective is also marked by resilience and innovation. For instance, the country’s response to the HIV/AIDS epidemic, once considered one of the world’s worst, has transformed over the years into a model of successful large-scale treatment and prevention. In the energy sector, South Africa is making strides towards renewable sources, with the government actively promoting wind and solar power projects.

Culturally, South Africa is often referred to as the “Rainbow Nation” due to its multicultural diversity. This diversity is reflected in its 11 official languages, various religious practices, and a wide range of traditions and customs. The South African perspective, therefore, encompasses a broad spectrum of experiences, views, and aspirations.

Yet, there are challenges. Issues like corruption, political instability, and social unrest often make headlines. The country’s education and healthcare systems, while having made progress, still need significant improvement. Crime rates, particularly violent crime, remain a pressing concern.

Despite these challenges, the South African perspective remains hopeful. The country’s vibrant civil society, free press, and robust legal system are all signs of a strong democracy. South Africans continue to strive for a more equitable and prosperous future, drawing strength from their past, learning from their present, and looking forward to their future.

Analysis of South Africa’s industrial landscape and the demand for butterfly valves.

South Africa’s industrial landscape is diverse and robust, with key sectors including mining, manufacturing, energy, and water treatment. The mining industry, in particular, is a significant part of the country’s economy, contributing around 8% to the GDP. Butterfly valves, known for their durability and efficiency in controlling fluid flow, are extensively used in these industries. The demand for such valves, especially the air actuated type, is high due to their precise regulation of flow rates, quick response times, and automated control. In the energy sector, particularly in South Africa’s emerging renewable energy market, butterfly valves play a critical role in regulating fluid flows with high precision. Similarly, in water and wastewater treatment plants, these valves’ ability to handle large volumes of water and resist corrosion makes them invaluable. However, the choice between manual and air actuated butterfly valves largely depends on the specific needs of each industry. While manual valves are cost-effective and sufficient for smaller systems, air actuated valves are preferable for larger-scale applications where safety and efficiency are paramount.

Examination of local manufacturing capabilities for butterfly valve in South Africa.

South Africa’s local manufacturing capabilities for butterfly valves are robust and competitive, with several top suppliers operating in the region. Companies like AVK and Premier Valves are leading the way, with AVK notably exceeding the directive’s local content requirement of 70%, reaching an impressive 84% within its production. This strong local production not only fosters economic growth but also ensures a reliable supply of high-quality butterfly valves to various industries in the country. The locally manufactured Wouter Witzel butterfly valves from AVK Southern Africa have been commended for providing substantial cost savings and reducing personnel requirements. The South African valve industry is also supported by policies promoting local manufacturing, such as the valves designation policy. However, the local industry faces challenges, including intensified competition from other local producers and limited throttling, which may hamper the butterfly valve industry’s growt. Despite these challenges, South African manufacturers continue to innovate and improve, as seen in their adoption of advanced technologies like machine learning for modeling the performance of butterfly valves.

Impact of import/export dynamics on the butterfly valve market in South Africa.

The import/export dynamics significantly impact the butterfly valve market in South Africa. The country’s butterfly valve market is intertwined with global trade, with fluctuations in import/export activities influencing supply and demand, pricing, and revenue. The COVID-19 pandemic disrupted the global supply chain, affecting the local industry’s ability to source necessary parts or export finished products. Additionally, geopolitical tensions, like the Russia-Ukraine conflict, added further pressure on the global trade dynamics, impacting both the import and export of butterfly valves.

However, despite these challenges, South Africa’s butterfly valve market continues to grow. The Triple Offset Butterfly Valve Market in South Africa is expected to expand, indicating a positive outlook for the sector. The market’s growth is also driven by local manufacturing capabilities, which help reduce dependence on imports and mitigate global supply chain disruptions. Despite the complexities of global trade and external pressures, South Africa’s butterfly valve market remains resilient, adapting to changes and seizing opportunities for growth.

Conclusion

In conclusion, the choice between manual and air actuated butterfly valves in South Africa is a critical decision that hinges on several factors. Each valve type offers unique advantages that make it suitable for specific applications within different industries.

Manual butterfly valves, due to their simplicity, cost-effectiveness, and easy maintenance, have been an industry staple for years. Their versatility makes them a popular choice for smaller systems where precise control is not paramount. Manual butterfly valves are particularly beneficial in sectors like water treatment and certain manufacturing processes where cost considerations take precedence.

On the other hand, air actuated butterfly valves, with their advanced features, offer higher precision, automation, and safety. These valves have become increasingly popular in industries that require large-scale fluid control, such as mining, energy, and certain types of manufacturing. The ability of these valves to provide quick response times, automated control, and precise regulation of flow rates makes them ideal for these complex applications.

The South African industrial landscape, with its diverse sectors, demands both types of butterfly valves. Local manufacturers have risen to the challenge, producing high-quality butterfly valves that cater to the needs of different industries. The strong local production capabilities, coupled with supportive government policies, have fostered a thriving butterfly valve market in the country.

However, the industry also faces challenges. Global trade disruptions, competition from imported products, and technological advancements are some of the factors that could impact the market dynamics. South African manufacturers need to stay agile, innovate, and continually improve their products to stay competitive.

In the end, the choice between a manual and an air actuated butterfly valve will depend on the specific requirements of each application. Understanding the strengths and limitations of each type of valve is key to making an informed decision. As the South African industrial landscape continues to evolve, so too will the demand for these crucial components. It’s an exciting time for the butterfly valve industry in South Africa, filled with opportunities for growth and innovation.

Whether you operate in the mining, manufacturing, energy, or water treatment sector, remember that the right butterfly valve can significantly enhance your operations’ efficiency and safety. So, choose wisely, and don’t hesitate to seek expert advice when needed. The future of South Africa’s industrial sectors depends on the judicious use of resources, and butterfly valves play a pivotal role in this endeavour.

Recap of the main points discussed in the blog post.

In this blog post, we delved into the comparison between manual and air actuated butterfly valve from a South African perspective. We highlighted that manual butterfly valve, known for their simplicity, cost-effectiveness, and ease of maintenance, are often chosen for smaller systems where cost is a significant factor. Conversely, air actuated butterfly valve, offering higher precision, automation, and safety, are increasingly popular in large-scale fluid control industries like mining and energy. We underscored the local manufacturing capabilities in South Africa, which support the production of both types of valves, fostering a strong butterfly valve marine market. However, we also pointed out challenges such as global trade disruptions and competition. Ultimately, the choice between manual and air actuated butterfly valves depends on the specific requirements of each application, with the future of South Africa’s industrial sectors hinging on the judicious selection and use of these crucial components.

Final thoughts on the choice between manual and air actuated butterfly valve in South Africa.

In closing, the choice between manual and air actuated butterfly valve in South Africa is not a one-size-fits-all decision, but rather, it’s a strategic choice that should be based on the specific needs and constraints of each application. Both types of valves have their unique advantages and potential drawbacks. Manual butterfly valve might be the preferred choice for cost-effectiveness and simplicity, especially in smaller systems. However, for industries requiring large-scale fluid control with precise regulation, air actuated butterfly valve, with their automation and safety features, may be the more suitable choice. It’s crucial that South African industries consider their unique operational requirements, budget constraints, and future growth plans when making this decision. As the country’s industrial landscape continues to evolve, the innovation and adaptation in the butterfly valve market will undoubtedly play a pivotal role in driving efficiency and sustainability.

Encouragement for readers to share their experiences and thoughts on the topic.

We hope this blog post has provided you with valuable insights into the manual and air actuated butterfly valve within the South African context. We understand that many of our readers are industry professionals with firsthand experience in using these tools, and your perspectives could greatly benefit others navigating similar decisions. We encourage you to share your experiences, thoughts, and insights on this topic. Have you found one type of valve to be more beneficial in certain situations? How have these valves impacted your operations? Your input can not only enrich the discussion but also help others make more informed decisions. Please feel free to leave your comments below or reach out to us directly. We look forward to hearing from you and continuing this important conversation.