Butterfly valves play an indispensable role in regulating and controlling the flow of fluids within numerous industrial systems. Among these, concentric and eccentric PN25 butterfly valves are two highly prevalent types, each boasting its own unique features and advantages. This post delves into a comprehensive comparative study between these two valve types. We will explore their design structures, functionalities, benefits, drawbacks, and real-world applications. Our objective is to provide insights that will guide your decision-making process when choosing between concentric and eccentric PN25 butterfly valves for your specific operational needs. Let’s dive in!

Introduction

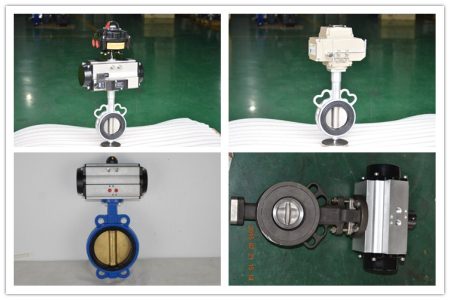

Butterfly valve, as a crucial component in fluid control systems, come in various designs with each serving specific functions. Among these, Concentric and Eccentric PN25 butterfly valves are two widely used types, each having its own set of unique features, advantages, and potential challenges. In a concentric butterfly valve, the stem is located in the center of the disc, and the disc is in the middle of the pipe bore. This design allows for a simple and compact structure, resulting in lower cost and easier installation. However, due to the disc’s constant contact with the seat, there can be more wear and tear over time, potentially leading to leakage issues. On the other hand, Eccentric PN25 butterfly valves have their stem located off-center, allowing the disc to move off the seat, reducing its contact and wear. This design results in a longer lifespan and better sealing performance, making it suitable for applications requiring tight shut-off. However, this comes at the expense of a more complex structure and higher cost. Therefore, when choosing between these two, one needs to consider various factors such as the application’s requirements for sealing performance, budget constraints, and maintenance capabilities. Both types of valves are designed to handle a pressure up to 25 bar (PN25), making them suitable for a wide range of industrial applications.

Brief explanation of what a butterfly valve is, its uses, and its importance in controlling fluid flow.

A butterfly valve is a type of flow control device, typically used to regulate a fluid flowing through a section of a pipe. The valve is named after the butterfly disc, the metal disc mounted on a rotating shaft, which forms its primary mechanism. When the valve is fully open, the disc aligns itself with the fluid flow allowing unrestricted movement of the fluid. However, when the valve is closed, the disc rotates to block the flow completely. Butterfly valves are crucial in various industrial applications including water supply, wastewater treatment, fire protection, and power generation due to their reliability, ease of operation, and low-pressure drop across the valve. They are particularly valued for their compactness and affordability compared to other types of valves. By efficiently controlling fluid flow, butterfly valves contribute significantly to the overall efficiency and safety of industrial systems.

Overview of the two main types of butterfly valves: Concentric and Eccentric PN25.

Concentric and Eccentric PN25 butterfly valves represent two main types of butterfly valves, each with its own unique characteristics and applications. In a Concentric butterfly valve, the stem is located in the center of the disc, and the disc itself is in the middle of the pipe bore. This configuration makes for a simple, compact, and cost-effective design that is easy to install and operate, making it a common choice for applications where the fluid compatibility and pressure temperature ratings are less demanding. However, because the disc is in constant contact with the valve seat, it can wear over time and potentially lead to leakage. On the other hand, an Eccentric PN25 butterfly valve features an off-center stem, which allows the disc to move away from the seat, thus reducing disc-seat contact and subsequent wear. This results in a longer lifespan of the valve and better sealing performance, making it more appropriate for applications requiring tight shut-off or dealing with abrasive fluids. The tradeoff is a more complex design and higher costs. Both these valves are rated for pressures up to 25 bar (PN25), making them suitable for a wide array of industrial applications. The choice between these two types of valves largely depends on the specific requirements of the application, including budget, maintenance capabilities, and performance needs.

Insights into the blog post objectives: comparative analysis of concentric and eccentric PN25 butterfly valves.

The primary objective of this blog post is to provide a comprehensive comparative analysis of Concentric and Eccentric PN25 butterfly valves, two of the most commonly used types in various industries. We aim to delve into the unique characteristics, advantages, and potential challenges associated with each type. Our goal is not only to explain the fundamental differences between these two valve designs but also to help readers understand the contexts in which one might be preferred over the other. By examining factors such as design complexity, cost, installation ease, sealing performance, lifespan, and maintenance requirements, we hope to equip our readers with the knowledge necessary to make informed decisions when selecting a butterfly valve for their specific applications. This comparison should serve as a useful guide for engineers, technicians, and anyone involved in the selection, installation, or maintenance of butterfly valves in industrial fluid control systems.

Understanding Butterfly Valves

Butterfly valves are a critical component in many industrial fluid control systems. They are essentially a type of quarter-turn valve that regulate or isolate the flow of fluid through pipes. The name ‘butterfly’ is derived from the distinct disc that sits in the center of the pipe, which, when viewed from the end, appears similar to the wings of a butterfly. This disc is mounted on a rod and when the valve is open, the disc aligns with the direction of the fluid flow and allows it to pass through. When the valve is closed, the disc rotates by 90 degrees and blocks the flow entirely. This simple operation mechanism makes butterfly valves easy to use and maintain.

There are different types of butterfly valves designed for various applications, including Concentric and Eccentric PN25 valves. Concentric butterfly valves have a straightforward design where the stem is located in the center of the disc, which itself is in the middle of the pipe bore. This makes them cost-effective and easy to install, but they may wear over time due to the constant disc-seat contact.

On the other hand, Eccentric PN25 butterfly valves feature an off-center stem that allows the disc to move away from the seat, reducing disc-seat contact and subsequent wear. This results in a longer lifespan and better sealing performance. However, these benefits come with a more complex design and higher costs. Both these valve types can withstand pressures up to 25 bar (PN25), making them suitable for various industrial applications.

The choice between different types of butterfly valves depends on several factors including the specific requirements of the application, budget, maintenance capabilities, and performance needs. Regardless of the type, butterfly valves play a vital role in controlling fluid flow, contributing to the efficiency and safety of industrial systems. They are used in a multitude of industries, from water supply and wastewater treatment to power generation and fire protection, highlighting their versatility and importance.

Description of how butterfly valves operate.

Butterfly valves operate on a fairly straightforward principle. They consist of a disc mounted on a rotating shaft. When the marine butterfly valve is fully open, the disc is positioned in a way that it allows for complete flow of the fluid. The disc is virtually parallel to the direction of the fluid flow and induces minimal obstruction. As the valve’s handle or actuator is turned, the disc rotates by 90 degrees around the stem – which is either centered in the disc or offset – until it’s perpendicular to the flow, thus blocking the passage and stopping the fluid flow completely, which is the closed position. The operation can be manual, using a handle, or automated, using an actuator. This quarter-turn mechanism is quick and allows for efficient regulation of flow, making butterfly valves an excellent choice for isolating or throttling services in various industrial applications.

Explanation of the different parts of a butterfly valve.

A butterfly valve is composed of several key components that work together to control fluid flow. The main parts include the body, disc, stem, and seat. The body is the outer casing that houses the internal components and connects to the piping system. It can be designed in various styles such as lug, wafer, or flanged, each suitable for different types of installations. The disc, which resembles a butterfly’s wings, is a central component that rotates to regulate or halt fluid flow. It is attached to the stem, a rod that passes through the body and allows for the rotation of the disc when an external force is applied. The stem can be either centered in the disc (concentric design) or offset (eccentric design), influencing the valve’s performance and sealing capabilities. The seat is another crucial component that forms a seal against the disc when the valve is closed, preventing any fluid leakage. It can be made of various materials depending on the application’s needs. Lastly, the valve may feature a handle or an actuator for manual or automatic operation respectively. Understanding these parts and their functions is vital for selecting the right butterfly valve for a specific application and for its proper maintenance.

Importance of valve ratings (such as PN25) in determining the pressure sustainability of a valve.

Valve ratings, such as PN25, play a crucial role in determining the pressure sustainability of a valve. The term ‘PN’ stands for ‘Pressure Nominale’ in French or ‘Nominal Pressure’ in English and represents the maximum pressure in bar that a valve can withstand at room temperature. For instance, a PN25 rating signifies that the valve can sustain up to 25 bar of pressure. These ratings are critical in ensuring the safe and efficient functioning of a valve within a system. If a valve is used in conditions exceeding its pressure rating, it could lead to valve failure, leakage, or even a catastrophic system breakdown. Therefore, understanding the pressure requirements of a system and selecting a valve with an appropriate rating is paramount to the overall performance and safety of the fluid control system. It’s also worth noting that these ratings can vary based on the material of the valve, the temperature of the operating environment, and the type of fluid being handled. Hence, all these factors must be considered while deciding on the suitable valve rating.

Concentric PN25 Butterfly Valves

Concentric PN25 Butterfly Valves are a specific type of butterfly valve designed for applications that require handling pressure up to 25 bar at room temperature. The ‘PN25’ designation indicates the maximum pressure these valves can withstand safely, making them suitable for moderate to high-pressure systems. The term ‘concentric’ refers to the design of the butterfly valve where the stem is centered in the middle of the disc and the disc is centered in the body of the valve. This concentric design allows for minimal disruption in the flow when the valve is open and provides a tight seal when closed. These valves are typically used in water distribution, HVAC, and other fluid control systems due to their robustness and reliability.

Despite their simplicity, Concentric PN25 Butterfly Valves offer effective flow control and isolation. They operate via a quarter-turn mechanism which enables quick and easy opening or closing, contributing to their efficiency. Furthermore, the compact and lightweight design of these valves makes them an economical choice for many industries. However, it’s important to note that due to the concentric design, there might be a slight leakage when the valve is fully closed.

The materials used for these valves can vary based on the application requirements, ranging from cast iron and stainless steel to more exotic alloys for special applications. The seat material in these valves is usually elastomeric, like EPDM or NBR, providing excellent sealing properties. The operation can be manual, using a handle, or automated, using an actuator. In conclusion, Concentric PN25 Butterfly Valves offer a reliable and cost-effective solution for controlling fluid flow in various industrial applications, provided that their limitations are taken into account.

Detailed explanation of what Concentric PN25 Butterfly Valves are.

Concentric PN25 Butterfly Valves are a type of quarter-turn valve that regulate or isolate the flow of a fluid. The ‘PN25’ in their name refers to the pressure rating, denoting that these valves can safely handle pressures up to 25 bar at room temperature. The term ‘concentric’ describes the configuration of the valve where the stem, the disc, and the body are all aligned along the same centerline. This design allows for a smooth flow of fluid when the valve is open, with minimal resistance.

The main components of this valve include the body, the disc, the stem, and the seat. The body houses all other parts and connects to the piping system. The disc, resembling a butterfly’s wings, rotates around the stem – which is centered in the disc – to control the flow of fluid. The seat forms a seal against the disc when the valve is closed, preventing fluid leakage.

These valves are lightweight, compact, and cost-effective, making them a popular choice for various industries such as water distribution and HVAC systems. They can be manually operated using a handle or automatically using an actuator. However, due to the concentric design, there might be slight leakage when the valve is fully closed. The materials used for these valves can vary depending on the application, with common choices being cast iron, stainless steel, and more exotic alloys for special applications. The seat is often made of elastomeric materials like EPDM or NBR for excellent sealing properties. Understanding these aspects is key to leveraging the full potential of Concentric PN25 Butterfly Valves in fluid control systems.

Description of their design, structure, and functionality.

Concentric PN25 Butterfly Valves have a unique design, structure, and functionality that make them ideal for regulating or isolating fluid flow in various systems. The valve is composed of four main parts: the body, the disc, the stem, and the seat. The body is the outer shell that houses all other components and connects to the pipe system. Inside the body, you’ll find the disc, which is the part that resembles the wings of a butterfly and is responsible for controlling the flow of fluid. This disc rotates around the stem, which is located in the center of the disc – hence the term ‘concentric’.

The seat of the valve forms a seal against the disc when the valve is closed, preventing any fluid from leaking. The materials used for these valves can vary depending on the application, but common choices include cast iron, stainless steel, and more exotic alloys for special applications. The seat is often made of elastomeric materials like EPDM or NBR, known for their excellent sealing properties.

In terms of functionality, Concentric PN25 Butterfly Valves operate via a quarter-turn mechanism. When the handle or actuator is turned, it causes the stem to rotate the disc either to an open or closed position. This simple yet effective mechanism allows for quick and easy control of fluid flow. However, due to the concentric design, there might be slight leakage when the valve is fully closed. Despite this, their lightweight, compact design, and cost-effectiveness make them a popular choice for various industries such as water distribution and HVAC systems.

Discussion on the benefits and potential drawbacks of using Concentric PN25 Butterfly Valves.

Concentric PN25 Butterfly Valves offer numerous benefits, which have led to their widespread use in various industrial applications. One of their primary advantages is their simple and compact design, allowing for easy installation and minimal space usage. This makes them an ideal choice for systems where space is at a premium. Moreover, their operation via a quarter-turn mechanism provides quick and efficient control of fluid flow, enhancing process efficiency.

Another significant advantage of these valves is their cost-effectiveness. They are typically less expensive than other types of valves with similar functionalities, making them a cost-efficient choice for many businesses. Additionally, they can handle pressures up to 25 bar, as indicated by the ‘PN25’ in their name, making them suitable for moderate to high-pressure systems.

However, Concentric PN25 Butterfly Valves also have some potential drawbacks. The most notable is the possibility of slight leakage when the valve is fully closed due to the concentric design. This may not be ideal for applications that require absolute zero leakage. Furthermore, while they can handle a wide range of pressures, they may not be suitable for extremely high-pressure or high-temperature applications. Lastly, the material of the valve’s seat, often made of elastomeric materials like EPDM or NBR, may not be compatible with certain types of fluids, potentially limiting their use in some industries. Therefore, while these valves offer many benefits, it’s crucial to consider these potential drawbacks when deciding if they are the right choice for a specific application.

Real-world applications and examples of where Concentric PN25 Butterfly Valves are commonly used.

Concentric PN25 Butterfly Valves are commonly used in a wide range of real-world applications due to their versatility, cost-effectiveness, and compact design. One of the most prevalent uses is in water distribution systems, where these valves regulate the flow of water through pipes, ensuring efficient supply to various sectors such as residential, commercial, and industrial areas.

Another significant application is in HVAC (Heating, Ventilation, and Air Conditioning) systems. These valves control the flow of coolant or heating fluids, contributing to the proper functioning of the system. They are also utilized in fire protection systems, given their quick operation, allowing for immediate isolation in case of an emergency.

In the industrial sector, these valves find use in various processes. For instance, they are used in the chemical industry for controlling the flow of different chemicals during production processes. In the food and beverage industry, they play a crucial role in managing the flow of various liquids during manufacturing.

However, it’s important to note that while Concentric PN25 Butterfly Valves are highly versatile, their suitability for a specific application depends on factors like the type of fluid, operating pressure, temperature, and potential compatibility issues with the material of the valve’s seat. Therefore, they may not be suitable for some industries or applications that require zero leakage or involve high-temperature or corrosive fluids.

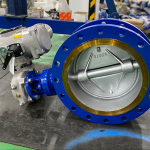

Eccentric PN25 Butterfly Valves

Eccentric PN25 Butterfly Valves, also known as offset butterfly valves, are a type of industrial valve that offers unique features and benefits due to their distinctive design. The term ‘eccentric’ or ‘offset’ refers to the placement of the stem in relation to the disc, which is not concentric as in traditional butterfly valves, but offset to one side. This results in a cam-like action during operation, where the disc lifts off the seat immediately upon opening, reducing wear and tear and leading to a longer lifespan of the valve.

The body of these valves can be made from various materials, including cast iron, stainless steel, and other alloys, depending on the application’s requirements. The disc, which controls the flow of fluid, is connected to the stem, which is turned to open or close the valve. The seat of the valve typically forms a seal against the disc when closed, preventing fluid leakage. However, unlike concentric butterfly valves, the eccentric design allows for a tighter seal when closed, virtually eliminating any leakage.

In terms of functionality, Eccentric PN25 Butterfly Valves operate via a quarter-turn mechanism, similar to their concentric counterparts. However, their eccentric design allows them to handle higher pressures and temperatures, making them suitable for more demanding applications. As indicated by ‘PN25’, these valves can handle pressures up to 25 bar, making them ideal for moderate to high-pressure systems.

Eccentric PN25 Butterfly Valves find widespread use in various industries due to their robustness, reliability, and excellent sealing properties. They are commonly used in water treatment plants, power generation facilities, oil and gas pipelines, chemical processing plants, and more. However, it’s important to consider that while these valves offer many advantages, they may be more expensive and require more space compared to concentric butterfly valves. Therefore, careful consideration should be given to the specific requirements of the application before choosing the type of butterfly valve to use.

Detailed explanation of what Eccentric PN25 Butterfly Valves are.

Eccentric PN25 Butterfly Valves, also known as offset butterfly valves, are a specialized type of industrial valve designed to regulate and isolate the flow of fluids. The term “eccentric” or “offset” refers to the unique design of these valves, where the stem or shaft is placed not in the center but offset from the center of the disc. This design results in a rotating disc moving away from the valve seat in an arc, reducing friction and wear on the sealing element during operation, thus ensuring a longer lifespan and better sealing compared to traditional concentric butterfly valves.

The ‘PN25’ in their name signifies the nominal pressure rating of these valves, indicating that they can handle pressures up to 25 bar, making them suitable for moderate to high-pressure applications. The body of these valves can be made from a variety of materials, including cast iron, stainless steel, and other durable alloys, depending on the specific requirements of the application.

The operation of Eccentric PN25 Butterfly Valves is achieved via a quarter-turn mechanism, which provides quick and efficient control of fluid flow. The disc, connected to the stem, rotates to open or close the valve, regulating the flow of the fluid. When closed, the disc forms a tight seal against the valve seat, preventing any leakage. This combination of efficient operation, excellent sealing properties, and durability makes Eccentric PN25 Butterfly Valves a popular choice in various industries, including water treatment, power generation, oil and gas, and chemical processing. However, it’s important to note that due to their complex design, these valves may be more expensive and require more installation space than their concentric counterparts.

Description of their design, structure, and functionality.

Eccentric PN25 Butterfly Valves are meticulously designed to offer optimal performance in various industrial applications. Their structure primarily consists of a circular disc, a stem, and a valve body. The defining characteristic of these valves is the eccentric or offset positioning of the stem, meaning it’s not located in the center of the disc but is placed off to one side.

This unique design allows the disc to move away from the valve seat in a cam-like or swinging motion as the valve is opened, reducing friction and wear on the sealing element. When fully opened, the disc aligns with the fluid flow, minimizing flow resistance and optimizing efficiency. On the other hand, when the valve is closed, the eccentric design enables the disc to establish a tight seal against the valve seat, virtually eliminating leakage.

The ‘PN25’ in their name indicates their nominal pressure rating, meaning that these valves can withstand pressures of up to 25 bar. This makes them ideal for moderate to high-pressure applications. The body of these valves can be constructed from various materials, including cast iron, stainless steel, and other alloys, depending on the specific application requirements.

In terms of functionality, Eccentric PN25 Butterfly Valves operate through a quarter-turn mechanism. This means that a 90-degree rotation of the stem results in a complete opening or closing of the valve, offering swift control of fluid flow. The operation can be manual, using a handwheel or lever, or automated, using actuators. While these valves provide numerous advantages such as excellent sealing capabilities and durability, they may require more installation space and could be more costly due to their complex design compared to concentric butterfly valves.

Discussion on the benefits and potential drawbacks of using Eccentric PN25 Butterfly Valves.

Eccentric PN25 Butterfly Valves offer several benefits that make them a preferred choice for many industrial applications. Firstly, their offset design reduces wear and tear on the valve seat, resulting in a longer lifespan and lower maintenance costs. This design also allows for a tighter seal when closed, virtually eliminating any leakage, which is critical in many industries such as oil and gas, chemical processing, and water treatment. Furthermore, these valves can handle higher pressures (up to 25 bar) and temperatures, making them suitable for more demanding applications.

Their quarter-turn operation enables quick and efficient control of fluid flow, contributing to improved process efficiency. The option to use manual or automatic actuation provides flexibility in different operational contexts. Moreover, the materials used for their construction, such as cast iron, stainless steel, and other alloys, ensure robustness and reliability even under harsh conditions.

However, despite these numerous advantages, there are potential drawbacks to consider. Due to their complex design, Eccentric PN25 Butterfly Valves may be more expensive than traditional concentric butterfly valves. They may also require more installation space, which could be a limitation in facilities where space is a constraint. Lastly, while they are designed to handle high pressures and temperatures, they may not be the best choice for extremely high-pressure or high-temperature systems, requiring careful consideration of application requirements before selection. Despite these potential drawbacks, the benefits and versatility of Eccentric PN25 Butterfly Valves often outweigh the challenges, making them a valuable component in many industrial settings.

Real-world applications and examples of where Eccentric PN25 Butterfly Valves are commonly used.

Eccentric PN25 Butterfly Valves are commonly employed in a wide range of real-world applications due to their unique design and robust performance. In the water treatment industry, these valves are used for controlling the flow of water in filtration systems and pipelines, thanks to their excellent sealing properties and ability to handle moderate to high pressures.

In the oil and gas sector, they serve a crucial role in controlling the flow of crude oil, natural gas, and other petroleum products through pipelines. Their ability to provide tight shutoff makes them ideal for containing hazardous materials and preventing leaks.

In power generation plants, particularly in cooling systems and steam distribution networks, Eccentric PN25 Butterfly Valves are used to regulate fluid flow, contributing to efficient operations and energy savings.

The chemical processing industry also utilizes these valves due to their ability to withstand corrosive environments and resist wear from frequent operation. They can control the flow of various chemicals, ensuring safe and efficient production processes.

In HVAC systems, these valves are used for balancing, isolating, and regulating the flow of heating or cooling medium. Their quick operation and reliable sealing make them an excellent choice for such applications.

Even in food and beverage industries, these valves are often used because of their sanitary design and ease of cleaning, controlling the flow of liquids during various stages of processing.

These examples demonstrate the versatility and widespread use of Eccentric PN25 Butterfly Valves across different industries and applications.

Comparative Analysis: Concentric vs Eccentric PN25 Butterfly Valves

Concentric and Eccentric PN25 Butterfly Valves are two different types of butterfly valves that serve a similar purpose of controlling fluid flow in a variety of industrial applications, but they differ significantly in their design, performance characteristics, and suitable applications.

Starting with the concentric butterfly valves, these valves are the simplest type of butterfly valves where the stem is located in the center of the disc, and the disc is in the middle of the valve body. This symmetrical design allows for a bi-directional flow and makes the valve relatively easy to manufacture and cost-effective. They are ideal for applications requiring low to moderate pressures and temperatures, such as water distribution systems or HVAC applications. However, due to the disc always being in contact with the valve seat, these valves may experience more wear and tear, potentially reducing their lifespan.

On the other hand, Eccentric PN25 Butterfly Valves feature an offset design where the stem is located off the center of the disc. This design allows the disc to move away from the valve seat as the valve opens, reducing friction and wear on the sealing element, thereby contributing to a longer lifespan and lower maintenance costs. The eccentric design also provides a tighter seal when the valve is closed, making these valves suitable for applications requiring zero leakage, such as oil and gas or chemical processing industries. With their ability to handle higher pressures (up to 25 bar), they are preferred for more demanding applications. However, these benefits come at a cost, as Eccentric PN25 Butterfly Valves can be more expensive and require more space for installation compared to concentric butterfly valves.

In conclusion, the choice between concentric and Eccentric PN25 Butterfly Valves largely depends on the specific requirements of the application, such as the pressure and temperature conditions, the need for tight shutoff, available space, and budget considerations. Both types of valves have their advantages and potential drawbacks, and understanding these differences can help in making an informed decision.

Side-by-side comparison of Concentric and Eccentric PN25 Butterfly Valves.

When comparing Concentric and Eccentric PN25 Butterfly Valves side-by-side, several notable differences emerge. In terms of design, a concentric butterfly valve features a centrally located stem that aligns with the center of the disc and the valve body, resulting in a symmetrical configuration. On the other hand, an eccentric butterfly valve has an off-center stem placement, creating an offset between the disc and the valve seat.

These design variations lead to differences in performance and application suitability. Concentric butterfly valves, due to their simpler design, are typically more cost-effective and easier to install, making them a popular choice for applications with low to moderate pressure and temperature requirements. However, the disc’s constant contact with the valve seat can lead to increased wear and tear over time.

Eccentric PN25 Butterfly Valves, with their offset design, reduce friction between the disc and the seat, thereby enhancing durability and reducing maintenance needs. This design also allows for a tighter seal when the valve is closed, making it ideal for applications requiring minimal leakage, such as in the oil and gas and chemical processing industries. They’re also capable of handling higher pressures (up to 25 bar). However, these benefits come with a higher cost and larger installation space requirements compared to concentric butterfly valves.

In conclusion, the choice between Concentric and Eccentric PN25 Butterfly Valves will depend on specific application requirements, budget considerations, and available installation space.

Discussion on the key differences in design, functionality, and application between the two.

The key differences between Concentric and Eccentric PN25 Butterfly Valves lie in their design, functionality, and application suitability.

Design-wise, a concentric butterfly valve is characterized by a disc that is located in the middle of the pipe and a stem that is positioned in the center of the disc. This results in a symmetrical design where the disc rotates around the center. In contrast, an eccentric butterfly valve features an offset design where the stem is placed off-center, either behind or to one side of the disc.

This fundamental design difference translates to significant functional differences. A concentric butterfly valve’s disc is always in contact with the flow, even when fully open, which can lead to more wear and tear over time. However, they are simpler in design and therefore, often more cost-effective. On the other hand, the eccentric design allows the disc to completely move out of the flow path when the valve is fully open, reducing wear and offering a longer service life. Moreover, eccentric butterfly valves provide a tighter seal when closed, making them suitable for applications that require zero leakage.

When it comes to application suitability, concentric butterfly valves are typically used in low-pressure systems and for isolation services in water distribution, HVAC, and other similar systems due to their straightforward operation and lower cost. Eccentric butterfly valves, owing to their ability to handle higher pressures (up to 25 bar) and offer tight shut-off, are suitable for more demanding applications such as oil and gas, chemical processing, and power generation industries. However, these valves are more complex and may require more space and cost more compared to concentric butterfly valves.

Analysis of specific scenarios where one type may be more suitable than the other.

In certain scenarios, the choice between Concentric and Eccentric PN25 Butterfly Valves can be quite clear based on the specific requirements of the application.

For instance, in water distribution systems or HVAC applications where pressures and temperatures are relatively low, a concentric butterfly valve may be more suitable. Its cost-effectiveness and simplicity in design make it an excellent choice for these scenarios. It’s bi-directional flow capability, easy installation, and operation also contribute to its suitability for such less-demanding applications.

On the other hand, consider a scenario in the oil and gas industry where the control of fluid flow under high pressure is required, and zero leakage is paramount. In this case, an Eccentric PN25 Butterfly Valve would be more appropriate. Its offset design reduces friction and wear on the sealing element, thus contributing to a longer lifespan and lower maintenance costs. Additionally, the eccentric design provides a tighter seal when the valve is closed, making it ideal for applications requiring a high level of tightness.

Moreover, in chemical processing industries where corrosive fluids might be present, the Eccentric PN25 Butterfly Valve’s ability to fully lift the disc out of the flow path when open helps minimize contact with potentially damaging fluids, thus enhancing the valve’s durability and reliability in such harsh conditions. However, these benefits come at a higher cost and demand more space for installation compared to the concentric butterfly valves.

Conclusion

In conclusion, the choice between Concentric and Eccentric PN25 Butterfly Valves is not a one-size-fits-all decision but rather hinges on the specific demands of the application at hand. Both valve types have unique attributes that make them more or less suitable for different scenarios.

Concentric butterfly valves, with their simple and symmetrical design, offer cost-effectiveness and ease of installation. These characteristics make them an excellent choice for low-pressure systems like water distribution or HVAC applications where the conditions are not particularly harsh, and the requirements are relatively straightforward.

However, their design does mean the disc is always in contact with the flow, even when fully open. This can lead to more wear and tear over time, potentially shortening the valve’s lifespan and increasing maintenance needs.

On the flip side, Eccentric PN25 Butterfly Valves, thanks to their offset design, provide a tight seal when closed and reduce friction between the disc and the seat. These attributes result in enhanced durability, reduced maintenance needs, and the capability to handle higher pressures (up to 25 bar). Therefore, they’re ideal for more demanding applications like those found in the oil and gas or chemical processing industries where zero leakage and long service life are crucial.

However, these benefits come with a higher price tag and increased space requirements for installation compared to concentric butterfly valves. So, while they might offer superior performance in certain situations, the cost and space implications must also be taken into account.

In essence, both Concentric and Eccentric PN25 Butterfly Valves have their place in the world of fluid control. The key is to understand their strengths and weaknesses and match them to the specific requirements of your application. By doing so, you can ensure optimal performance, longevity, and cost-effectiveness of your chosen butterfly valve, whether it be concentric or eccentric.

Remember, the correct valve can significantly impact the efficiency and safety of your operations. Therefore, it’s crucial to partner with a knowledgeable valve supplier who can guide you in making the right choice based on your unique needs and provide quality products that will stand the test of time.

Recap of the main points discussed in the blog post.

To recap, this blog post delved into a comparative study between Concentric and Eccentric PN25 Butterfly Valves, focusing on their design, functionality, and application suitability. Concentric butterfly valves, with their symmetrical design, offer cost-effectiveness and are suitable for low-pressure systems like water distribution or HVAC applications. However, they may experience more wear and tear due to the disc’s constant contact with the flow.

On the other hand, Eccentric PN25 Butterfly Valves, with their offset design, provide enhanced durability, reduced maintenance needs, and the ability to handle higher pressures. They are ideal for more demanding applications found in industries like oil and gas or chemical processing where zero leakage and long service life are crucial. But, these benefits come at a higher cost and increased space requirements for installation.

The choice between these two types of valves depends largely on the specific requirements of your application. Therefore, it is necessary to understand their strengths and weaknesses and match them to your unique needs to ensure optimal performance, longevity, and cost-effectiveness.

Final thoughts on choosing between Concentric and Eccentric PN25 Butterfly Valves based on specific needs and applications.

In conclusion, the decision between Concentric and Eccentric PN25 Butterfly Valves should be primarily driven by the specific needs and applications of your operations. For less demanding environments with low pressures and temperatures, such as water distribution systems or HVAC applications, a concentric butterfly valve may serve you well due to its cost-effectiveness and simplicity in design. However, for more demanding and high-pressure applications like those found in the oil and gas industry or chemical processing plants, an eccentric butterfly valve, despite its higher cost, would provide enhanced durability, reduced maintenance, and better sealing capabilities. Understanding these nuances is vital in making an informed choice. Therefore, it’s always beneficial to seek advice from a knowledgeable valve supplier who can guide you to the most suitable solution for your unique operational requirements.

Encouragement for readers to contact experts or the blog’s author for further advice tailored to their unique circumstances.

We understand that choosing the right valve for your operations can be a complex task given the variety of options available and the technical nature of these products. Therefore, we strongly encourage you to reach out to experts or even to us, the authors of this blog post, for further advice tailored to your unique circumstances. With our extensive knowledge and experience in this field, we can help guide your decision-making process, ensuring you select the most suitable butterfly valve—be it Concentric or Eccentric PN25—for your specific needs. Remember, making the right choice can significantly impact the efficiency, safety, and cost-effectiveness of your operations. So, don’t hesitate to seek expert advice—it’s an investment that will pay off in the long run.

-150x150.jpg)