Selecting the best stainless steel butterfly valves manufacturers is a crucial decision that can significantly impact the efficiency and longevity of your industrial systems. Butterfly valves play a vital role in controlling the flow of fluids in various applications, and opting for high-quality products from a reliable source is essential to ensure optimal performance and durability. This article will guide you through the key factors to consider when choosing a stainless steel butterfly valve manufacturer, helping you make an informed decision that meets your project requirements and delivers long-lasting results.

Introduction

Choosing the best stainless steel butterfly valve manufacturer is a critical task that requires careful consideration of several factors to ensure the optimal performance and durability of your industrial systems. High-quality butterfly valves play an essential role in controlling fluid flow in various applications, such as water treatment plants, chemical processing facilities, and oil refineries. When selecting a manufacturer, it’s vital to consider their industry experience and reputation, as this can be a strong indicator of their ability to produce reliable and efficient products. Certifications and compliance with industry standards, such as ISO, API, and CE, are also crucial, as they reflect the manufacturer’s commitment to quality control and adherence to best practices. Additionally, it’s important to examine the range of products offered by the manufacturer and their ability to provide customized solutions tailored to your specific project requirements. The quality of materials used in the manufacturing process should not be overlooked, as high-grade stainless steel ensures corrosion resistance and overall durability. Furthermore, adequate technical support and after-sales service are essential aspects to consider, as they can significantly impact your overall satisfaction and the product’s lifespan. Lastly, comparing prices among different manufacturers without compromising on quality, and evaluating delivery timeframes and reliability, can help you make the best decision for your industrial needs. By taking these factors into account, you can confidently choose a stainless steel butterfly valve manufacturer that meets your expectations and guarantees long-lasting results.

Briefly explain what a stainless steel butterfly valves is and its applications

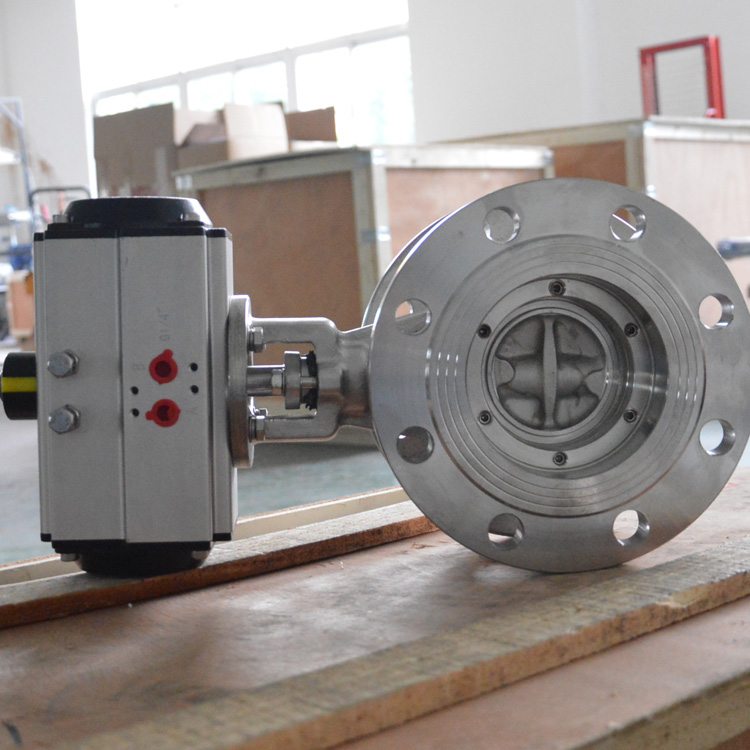

A stainless steel butterfly valve is a flow control device designed for regulating and isolating the flow of fluids in various industrial systems. It consists of a circular disc mounted on a rotating shaft, which operates by turning the disc either parallel or perpendicular to the fluid flow. When fully open, the disc allows unrestricted passage, while rotating it to a closed position blocks the flow. The use of stainless steel as the primary material ensures high resistance to corrosion and enhanced durability, making these valves suitable for a wide range of applications. Stainless steel butterfly valves are commonly used in industries such as water treatment, chemical processing, food and beverage, pharmaceuticals, and oil and gas, where precise flow control and robust performance are essential. Their compact design, ease of operation, and low maintenance requirements make them a popular choice for managing fluid flow in various industrial settings.

Importance of selecting a high-quality butterfly valve manufacturer for your project

Selecting a high-quality butterfly valve manufacturer for your project is of utmost importance, as it directly impacts the performance, reliability, and longevity of your industrial systems. A reputable manufacturer with a proven track record in producing top-notch butterfly valves ensures that you receive products built with precision engineering, utilizing premium materials and adhering to strict quality control standards. By opting for high-quality butterfly valves, you can significantly reduce the risk of leaks, malfunctions, or premature wear, which translates into lower maintenance costs and minimal downtime for your operations. Moreover, a reliable manufacturer will often provide exceptional technical support and after-sales service, ensuring that any issues are promptly addressed and resolved. In essence, investing in a high-quality butterfly valve manufacturer not only guarantees optimal performance for your fluid control systems but also contributes to the overall efficiency and success of your project.

Factors to Consider When Choosing a Manufacturer

When choosing a butterfly valve manufacturer, several factors must be taken into account to ensure the selection of a reliable and high-quality supplier. First and foremost, industry experience and reputation play a vital role in determining the manufacturer’s capability to produce efficient and durable products. A well-established manufacturer with a proven track record in delivering top-notch butterfly valves is more likely to meet your specific project requirements. It’s essential to check customer reviews and testimonials to gain insights into their overall performance and satisfaction levels. Secondly, certifications and compliance with industry standards, such as ISO, API, and CE, are crucial indicators of the manufacturer’s commitment to maintaining high-quality control processes and adhering to best practices. Thirdly, evaluate the product range and customization options offered by the manufacturer. A diverse portfolio of stainless steel butterfly valves and their ability to provide tailored solutions can significantly contribute to the success of your project. Material quality and durability are other critical aspects to consider, as high-grade stainless steel ensures corrosion resistance and extended service life. Additionally, it’s essential to assess the level of technical support and after-sales service provided by the manufacturer. Prompt and efficient assistance throughout the purchasing process and beyond can significantly impact your overall satisfaction and the product’s lifespan. Finally, it’s important to compare pricing and delivery timeframes among different manufacturers without compromising on quality. Balancing cost-effectiveness with reliability and performance will enable you to make the best decision for your industrial needs. By carefully considering these factors, you can confidently select a stainless steel butterfly valve manufacturer that aligns with your expectations and delivers long-lasting results.

Industry Experience and Reputation

Industry experience and reputation are crucial factors to consider when selecting a stainless steel butterfly valves manufacturers. A company with extensive experience in the industry is more likely to have honed their expertise, developed efficient manufacturing processes, and established a solid understanding of customer needs. A good reputation, built on years of consistently delivering high-quality products and excellent customer service, is a strong indicator of a reliable and trustworthy manufacturer. It is essential to research the manufacturer’s history, past projects, and customer testimonials to gauge their performance in the market. By choosing a well-established and reputable manufacturer, you increase the likelihood of receiving top-notch butterfly valves that meet your project requirements and ensure optimal performance and durability of your fluid control systems.

Certifications and Compliance

Certifications and compliance with industry standards are essential factors to consider when selecting a stainless steel butterfly valve manufacturer, as they reflect the company’s commitment to quality control and adherence to best practices. Accreditations such as ISO, API, and CE demonstrate that the manufacturer has met stringent criteria and follows internationally recognized guidelines in their production processes. These certifications also indicate that the manufacturer consistently maintains high-quality levels, ensuring that their products meet or exceed performance and safety expectations. By choosing a manufacturer with the necessary certifications and compliance, you can be confident that you are investing in reliable and high-quality butterfly valves that will contribute to the efficiency and longevity of your industrial systems.

Product Range and Customization Options

Product range and customization options play a crucial role in determining the success and competitiveness of a business in today’s dynamic market landscape. A comprehensive product range showcases a company’s ability to cater to diverse customer needs, spanning across various industries and applications. This adaptability not only helps in attracting a broader customer base but also fosters long-term relationships by offering tailored solutions to individual requirements. Furthermore, customization options demonstrate a company’s commitment to innovation and customer satisfaction, as they invest time and resources to modify their products according to unique specifications. Ultimately, a robust product range combined with extensive customization possibilities paves the way for a truly customer-centric business model, driving growth and fostering brand loyalty.

Material Quality and Durability

Material quality and durability are paramount factors in determining the longevity and performance of any product, particularly in industries where reliability is of utmost importance. High-quality materials ensure that products meet or even exceed industry standards, resulting in improved functionality and resistance to wear and tear. Durability, on the other hand, speaks to a product’s ability to withstand harsh conditions and maintain its structural integrity over time. By investing in materials of superior quality and engineering products with durability in mind, manufacturers not only guarantee optimal performance but also minimize the need for frequent replacements or repairs. This ultimately translates to cost savings and increased efficiency for the end user, bolstering customer satisfaction and trust in the brand.

Technical Support and After-sales Service

Technical support and after-sales service play a crucial role in fostering customer satisfaction and maintaining long-term business relationships. These services ensure that customers receive prompt assistance in resolving any product-related issues or concerns that may arise during installation, operation, or maintenance. By providing timely and effective technical support, companies demonstrate their commitment to customer success, instilling confidence in the reliability and performance of their products. Moreover, comprehensive after-sales service, including warranty coverage, spare parts availability, and maintenance support, adds value to the overall purchasing experience. Ultimately, exceptional technical support and after-sales service not only contribute to increased customer retention but also help build a strong brand reputation, driving growth and market expansion for the company.

Pricing and Delivery Timeframes

Pricing and delivery timeframes are vital aspects of any business transaction, significantly influencing the customer’s decision-making process and overall satisfaction. Competitive pricing reflects a company’s understanding of market dynamics and its commitment to offering cost-effective solutions without compromising on quality or performance. By providing products at reasonable prices, businesses can attract a wider customer base and maintain an edge over their competitors. Additionally, timely delivery demonstrates a company’s efficiency in managing supply chain processes and meeting customer expectations. Prompt delivery not only helps in building trust and credibility but also ensures that clients can meet their project deadlines and avoid potential delays. In essence, striking a balance between competitive pricing and efficient delivery timeframes is essential for a successful business strategy, fostering customer loyalty and driving long-term growth.

Tips for Finding the Right Manufacturer

When searching for the right manufacturer to meet your specific needs, several factors should be carefully considered to ensure a successful partnership that delivers high-quality products and services. First and foremost, it’s essential to evaluate the manufacturer’s industry experience and expertise, as this can provide valuable insight into their reliability and track record in delivering exceptional results. In addition, researching customer testimonials and case studies can offer a glimpse into the company’s performance and how well they address client requirements. Secondly, assess the manufacturer’s product range and customization options, as these attributes demonstrate their ability to cater to diverse needs and tailor products according to unique specifications. This versatility is crucial in finding the perfect fit for your project.

Another critical factor to consider is the quality of materials used and the durability of the products offered. High-quality materials and robust design contribute to a product’s longevity and optimal performance, ultimately leading to cost savings and increased efficiency. Furthermore, investigate the manufacturer’s commitment to innovation and staying updated with the latest industry developments and technologies. This can help ensure that you receive cutting-edge solutions and maintain a competitive edge in your respective market.

Technical support and after-sales service are also essential aspects to examine when selecting a manufacturer. Prompt and effective technical assistance, coupled with comprehensive after-sales services such as warranty coverage and maintenance support, can significantly impact customer satisfaction and long-term business relationships. Moreover, evaluate the manufacturer’s pricing strategy and delivery timeframes. Competitive pricing and efficient delivery processes showcase a company’s ability to balance cost-effectiveness with prompt service, resulting in a positive customer experience.

Lastly, consider the manufacturer’s certifications and adherence to industry standards. Compliance with relevant regulations and certifications signifies their commitment to maintaining high-quality standards and ensuring product safety. By taking the time to thoroughly assess these factors, you can make an informed decision and partner with a manufacturer that aligns with your specific needs and objectives, paving the way for a successful and mutually beneficial collaboration.

Conducting thorough research and comparing multiple manufacturers

Conducting thorough research and comparing multiple manufacturers is an essential step in selecting the ideal partner for your business needs. This process allows you to gain valuable insights into each manufacturer’s strengths, weaknesses, and unique offerings, enabling you to make an informed decision based on a comprehensive understanding of the market landscape. By evaluating factors such as industry experience, product range, customization options, material quality, technical support, and pricing strategies, you can identify the manufacturer that best aligns with your specific requirements and objectives. Furthermore, considering customer testimonials and case studies can provide a more accurate picture of a company’s performance and commitment to customer satisfaction. Ultimately, investing time and effort into researching and comparing manufacturers not only increases the likelihood of finding the perfect fit for your project but also fosters long-term, successful partnerships that drive growth and innovation in your industry.

Seeking recommendations from industry peers or online forums

Seeking recommendations from industry peers or online forums can be an invaluable resource in the quest to find a reliable and suitable manufacturer for your business needs. Tapping into the collective knowledge and experiences of colleagues, industry experts, or even fellow entrepreneurs allows you to gather firsthand information on manufacturers’ performance, quality, and customer service. These insights can help you identify potential partners that have a proven track record of delivering exceptional results in your specific field or sector. Online forums and discussion groups also offer a platform for unbiased feedback and opinions, enabling you to gain a more comprehensive understanding of various manufacturers’ strengths and weaknesses. By leveraging the power of networking and shared experiences, you can make more informed decisions and select a manufacturing partner that not only meets but exceeds your expectations, ultimately contributing to the long-term success of your business endeavors.

Requesting product samples and evaluating their performance

Requesting product samples and evaluating their performance is a critical step in the process of selecting the right manufacturer for your business needs. By obtaining and thoroughly examining samples, you can assess the quality of materials used, craftsmanship, and overall functionality of a manufacturer’s offerings. This hands-on approach allows you to determine whether the products meet your specific requirements and industry standards, ensuring that you make an informed decision based on tangible evidence. Additionally, testing the samples under real-life conditions or simulating the intended usage environment can provide valuable insights into their durability and performance capabilities. This practical evaluation not only helps to identify potential issues or areas for improvement but also instills confidence in the chosen manufacturer’s ability to deliver high-quality products that align with your expectations. Ultimately, requesting and scrutinizing product samples serves as a vital checkpoint in the manufacturer selection process, minimizing risks and maximizing the likelihood of a successful partnership.

Conclusion

In conclusion, selecting the best stainless steel butterfly valves manufacturers is a critical decision that can significantly impact your business’s performance, efficiency, and long-term success. To navigate this crucial process, it is essential to consider several key factors that contribute to a fruitful partnership with a manufacturer who consistently delivers high-quality products.Firstly, conduct thorough research and compare multiple manufacturers to gain a comprehensive understanding of their offerings, strengths, and weaknesses. This information will enable you to make an informed decision based on each manufacturer’s ability to meet your specific requirements and industry standards.Secondly, seek recommendations from industry peers or online forums to gather firsthand information on manufacturers’ performance, quality, and customer service. This invaluable resource can help you identify potential partners with a proven track record in delivering exceptional ss butterfly valves.

Requesting product samples and evaluating their performance is another vital step in selecting the right manufacturer. By obtaining and thoroughly examining samples, you can assess the quality of materials used, craftsmanship, and overall functionality of a manufacturer’s products. Testing the samples under real-life conditions or simulating the intended usage environment can provide valuable insights into their durability and performance capabilities. Additionally, consider the manufacturer’s commitment to innovation and staying updated with the latest industry developments and technologies. Partnering with a company at the forefront of technological advancements ensures that you receive cutting-edge solutions and maintain a competitive edge in your respective market.Technical support and after-sales service are also crucial aspects to examine when selecting a manufacturer. Prompt and effective technical assistance, coupled with comprehensive after-sales services such as warranty coverage and maintenance support, can significantly impact customer satisfaction and long-term business relationships.

Furthermore, evaluate the manufacturer’s certifications and adherence to industry standards. Compliance with relevant regulations and certifications signifies their commitment to maintaining high-quality standards and ensuring product safety.Finally, take into account the manufacturer’s pricing strategy and delivery timeframes. Competitive pricing and efficient delivery processes showcase a company’s ability to balance cost-effectiveness with prompt service, resulting in a positive customer experience.By meticulously assessing these factors and dedicating time and effort to the selection process, you can confidently choose the best stainless steel butterfly valve manufacturer that aligns with your specific needs and objectives. Ultimately, this will pave the way for a successful and mutually beneficial collaboration that drives innovation, strengthens market competitiveness, and contributes to your business’s long-term growth.

Recap the importance of selecting a reliable stainless steel butterfly valves manufacturers

To recap, selecting a reliable stainless steel electric butterfly valve manufacturer is of paramount importance for businesses that rely on high-quality valves for their operations. A dependable manufacturer ensures consistent product performance, durability, and adherence to industry standards, which directly impacts efficiency, customer satisfaction, and overall business success. By thoroughly evaluating factors such as industry experience, product range, material quality, innovation, technical support, pricing strategies, and compliance with regulations, businesses can identify the ideal manufacturing partner that meets their specific requirements. Investing time and effort into this selection process ultimately fosters long-term, successful collaborations that drive growth, innovation, and competitiveness in an ever-evolving market landscape.

Encourage readers to keep the outlined factors in mind while making their decision

We encourage readers to keep the outlined factors in mind while making their decision to select a reliable stainless steel butterfly valve manufacturer. By thoroughly researching and comparing multiple manufacturers, seeking recommendations from industry peers or online forums, evaluating product samples, and considering aspects such as innovation, technical support, pricing strategies, and compliance with regulations, businesses can make well-informed choices that align with their specific needs and objectives. Remember that investing time and effort into this crucial selection process helps foster long-term, successful partnerships that contribute to your business’s growth, innovation, and competitiveness in today’s dynamic market landscape. So, take your time, weigh your options carefully, and choose a manufacturer that truly understands and supports your goals for a fruitful collaboration.