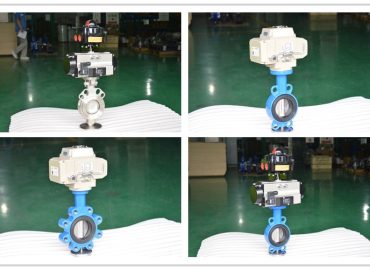

Whether it’s controlling the flow of water, gas, steam, or any other fluid, the pneumatic butterfly valve is one of the most common and reliable valves available. It comes in several different styles, configurations and options that can be tailored to suit a variety of applications and systems. In this blog post, we’ll provide an overview of the various styles and configurations available for three inch butterfly valves to help you make an informed decision when selecting the type of valve needed for your application.

Introduction

When looking to purchase and install a 6 inch butterfly valve, it is important to understand the various styles and configurations available. With multiple options available, such as lever operated, wafer style, and lug style valves, it is essential to select the right valve for the job in order to ensure long term reliability and optimal performance. Furthermore, there are several configuration options that should be considered when selecting a butterfly valve for installation, such as single port vs double port valves and automated vs manual operation. Knowing the types of 3 inch butterfly valves available and understanding the various configuration options will help ensure that you get the best valve for your system.

Types of 3 Inch Butterfly Valves

When it comes to the types of 3 inch butterfly valves available, there are three main categories: lever operated, wafer style, and lug style. Lever operated butterfly valves have a handle attached to the valve disc which allows for manual operation. These valves are easy to install and maintain and are typically used in industrial settings where frequent access is needed. Wafer style butterfly valves are designed with two metal plates that form a seal when the valve is closed. They feature a low cost, lightweight design and are usually reserved for situations where computerized control is not necessary.

Lug style butterfly valves have bolted ends mitering the two side chambers, allowing for secure connection between two pipes. These models can be automated, making them ideal for use in various applications such as water processing plants or chemical manufacturing sites.

Lever Operated

Lever operated butterfly valve are popular for manual operation due to their ease of installation and maintenance. This type of valve generally consists of a handle that is attached to the valve disc in order to open or close it. Lever operated butterfly valves are commonly used in industrial settings where frequent access is needed, such as water processing plants or chemical manufacturing sites. butterfly valve price

Their straightforward design also makes them ideal for less complex applications, such as general service in residential plumbing systems. These valves can be made from a variety of materials, including brass, stainless steel, or even bronze in some cases. With all these options available, lever operated butterfly valves provide an affordable and reliable solution for many types of operations.

Wafer Style c. Lug Style

Wafer style butterfly valves feature two metal plates that create a seal when the valve is closed. This type of valve is lightweight and cost effective, making it ideal for situations where computerized control is not necessary. Additionally, they are generally easy to install as they require no additional mounting hardware. Lug style butterfly valves are bolted at either end and connect two side chambers in order to form secure connections between two pipes. This configuration can be automated, making them perfect for use in various applications such as water processing plants or chemical manufacturing sites. Furthermore, this model provides a tight seal for reliable operation, even when exposed to high temperatures and pressure levels.

Configuration Options for 3 Inch Butterfly Valves

There are a number of different configuration options available for lug butterfly valves. From manual to automated solutions, users can find the perfect solution that offers the precise functionality they require. Manual lever operated butterfly valves are easy to install and maintain due to their straightforward design and user friendly handle that open or close the valve with a simple flip of the wrist. Automated models feature actuator components such as pneumatic cylinders and electric motors that allow users to control the valve from a distance. A broad range of materials, such as brass, stainless steel, and bronze are also available to offer greater protection against corrosion or high temperatures and pressure levels. Additionally, some models come with integrated external hinges that provide an even more secure connection between two pipes when used in installations that require frequent access. With so many options on the table, 3 inch butterfly valves offer reliable solutions for various operations.

Single Port vs Double Port

Single port and double port butterfly valves differ in design and function. Single port models feature a cylindrical valve body with a single inlet and outlet for the media being regulated. This kind of valve is often used when there is only one line of flow or a direct connection between two points is desired. On the other hand, double port valves feature two separate entry ports – an inlet side (inflow) and an outlet side (outflow).Double port configurations are ideal for applications that require higher levels of flow control, as they offer more precise regulation of fluid pressure. urthermore, they can be motorized to allow users to better adjust the rate of flow.

Automated vs Manual Operation

Automated and manual butterfly valves represent two different levels of operation. Automated versions feature actuator components such as pneumatic cylinders or electric motors that can open/close the valve when instructed to do so. This allows users to control the valves from a distance, offering flexibility and more consistent performance over time. On the other hand, manual lever-operated butterfly valves offer simpler solutions that require no external power sources. With easy installation and maintenance, as well as user-friendly handles for opening or closing the valve with a simple flip of the wrist, this type of valve remains a popular option in many industrial applications.

Benefits of Installing 3 Inch Butterfly Valves

Installing wafer butterfly valves can provide a number of key benefits to industrial operations. Most notably, the size and shape of the valve body allows it to be installed in tight spaces, making it ideal for applications with limited space or where frequent movement and repositioning may be required. Additionally, these valves are extremely durable due to their robust construction and materials. This makes them ideal for handling high pressure and temperature fluctuations as well as abrasive media such as slurries or debris-laden liquids.

Furthermore, the fact that these valves are relatively lightweight makes them easy to install and transport from one location to another with minimal effort or stress on equipment or personnel. Finally, 3 inch butterfly valves come equipped with lever handles that make it easy for operators to open/close the valve quickly without having to reach into confined spaces.

Conclusion

In conclusion, 3-inch butterfly valves offer a number of distinct advantages to industrial operations. With easy installation and maintenance, as well as robust construction and materials that handle high pressures and temperatures, these valves are ideal for tight spaces or sites with frequent movement and repositioning. Furthermore, their lightweight design makes them easy to transport or maneuver into the most confined areas. Finally, their lever handles allow operators to quickly open/close the valve without having to reach into tight spots. With all this in mind, it’s clear why 3-inch butterfly valves are such a popular choice in many industrial applications.

-370x270.jpg)