In any industrial setup, the smooth operation of machinery is paramount to efficiency and productivity. One essential component that often goes unnoticed yet plays a critical role in such setups is the butterfly disc valve. These valves control the flow of fluids in a system, ensuring continuity and preventing potential disasters. However, their effectiveness is largely dependent on proper installation and regular maintenance. This blog post provides a comprehensive guide on the installation and maintenance of butterfly disc valves. It covers everything from the basics of what a butterfly disc valve is, to the step-by-step process of installing one, to effective maintenance practices, and troubleshooting common issues. So whether you’re an experienced technician or a novice just starting out, this guide has something for you.

Introduction

Butterfly disc valves are integral components in various industrial applications, helping control and regulate the flow of fluids within a system. Their efficient operation, however, hinges on correct installation and regular maintenance. The installation process begins with preparing the necessary tools and ensuring safety measures are in place. The butterfly valve should be stored in a clean, dry, and corrosion-free environment if not installed immediately after purchase. During installation, the disc should be in the closed position, and its opening position determined based on the rotation angle of the disc. Once installed, the valve should be cycled at least once a month, especially if it’s not used regularly. Before any maintenance procedure, it’s crucial to relieve the system pressure to avoid accidents. Regular maintenance includes checking for leaks or damages, cleaning the valve, lubricating moving parts, and examining the sealing. If issues arise, some can be diagnosed and fixed using troubleshooting guides. However, in some cases, it may be necessary to seek professional help. Understanding the different types of butterfly valves, including wafer style butterfly valve, lug style butterfly valve, and flanged butterfly valve, is also important as each type has unique installation and maintenance requirements. Ultimately, proper installation and maintenance practices not only enhance the valve’s efficiency but also prolong its lifespan, saving time and money in the long run.

Brief overview of the blog post

Welcome to our latest blog post, where we explore the intricacies of butterfly disc valve installation and maintenance. This comprehensive guide will delve into the fundamentals of what a butterfly disc valve is, its key role in various industries, and the different types available. We’ll guide you through the entire installation process, outlining the necessary tools, safety precautions, and step-by-step instructions. Additionally, we will shed light on post-installation checks and initial operation testing to ensure optimal performance. But our exploration won’t stop at installation; we’ll also provide you with a detailed maintenance schedule, tips for troubleshooting common issues, and advice on when it’s time to call in professional help. Whether you’re a seasoned engineer or a beginner in the field, this guide aims to become your go-to resource for everything related to butterfly disc valves.

Importance and use of butterfly disc valves in various industries

Butterfly disc valves are a cornerstone in numerous industries due to their efficiency, reliability, and versatility. These valves play a crucial role in controlling and managing the flow of fluids – be it gas, water, or other liquid substances. Industries such as oil and gas, water treatment, power generation, HVAC, and even food and beverage heavily rely on these valves. In the oil and gas industry, for instance, butterfly valves are used in pipelines to regulate the flow of oil and gas, ensuring smooth operation while preventing potential disasters. In the water treatment sector, they are utilized for isolation and throttling services. The power generation industry uses them in cooling water systems, feed water systems, and scrubbing systems. Butterfly valves’ ability to maintain and control flow makes them invaluable in HVAC systems, where they assist in balancing the flow of air or water. Even in the food and beverage industry, these valves are essential for maintaining hygienic conditions by controlling the flow of ingredients during production. Hence, the importance of butterfly disc valves cannot be overstated, given their wide range of applications across different industries.

What is a Butterfly Disc Valve?

A butterfly disc valve, commonly known as a butterfly valve, is a type of quarter-turn valve that regulates the flow of fluid. The “butterfly” in its name refers to the metal disc mounted on a rotating shaft inside the valve. When the valve is fully opened, the disc aligns with the direction of the flow, allowing fluid to pass through unhindered. Conversely, when the valve is closed, the disc is turned so that it completely blocks off the path of the flow. The disc’s position can also be adjusted to any point between these two extremes, providing for accurate control over the rate of flow. Butterfly valves are widely appreciated for their durability, ease of operation, and cost-effectiveness. They are lightweight and require less support, making them advantageous over other types of valves, such as gate or globe valves. They are available in various designs – including wafer, lug, and flanged styles – to cater to different application requirements. These valves find usage across a broad spectrum of industries, from oil and gas to water treatment, power generation, HVAC systems, and even food and beverage production. Their ability to control and regulate fluid flow efficiently and effectively makes butterfly disc valves an indispensable component in many industrial operations.

Detailed explanation of butterfly disc valves

A butterfly disc valve is a quarter-turn rotational motion valve, used to stop, regulate, and start fluid flow. The valve gets its name from the disc that is central to its operation – a metal disc that is mounted on a rotating shaft. When the valve is open, this disc turns so that it allows fluid to pass through. When it’s closed, the disc turns to block the path of the fluid. The disc is positioned in the center of the pipe, and a rod passes through the disc to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow; therefore a pressure drop is always induced in the flow, regardless of the valve position. Butterfly valves are known for their quick operation and for being lighter and more compact than other types of valves. They’re often used in applications where space is at a premium, and they come in wafer and lug styles. Their simplicity, reliability, and range of uses make them a popular choice in many industries.

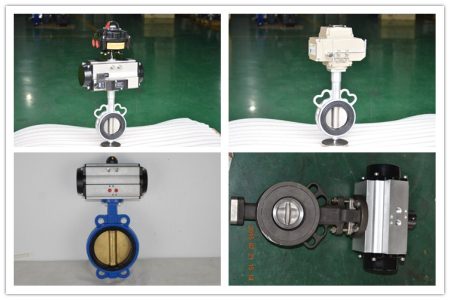

Different types and their specific applications

Butterfly disc valves come in various types, each suited to specific applications. The most common types include concentric, double-eccentric, and triple-eccentric butterfly valves. Concentric butterfly valves, also known as resilient-seated butterfly valves, have a rubber seat and are widely used in water distribution and food and beverage industries due to their tight seal. Double-eccentric butterfly valves, or high-performance butterfly valves, have an off-center stem that allows the disc to completely clear the path when open, reducing wear and tear. They’re often used in oil, gas, and power generation industries where higher pressure and temperature conditions prevail. Triple-eccentric butterfly valves, or triple offset valves, have a metal seat and feature a design that virtually eliminates wear, making them ideal for extreme temperature and pressure applications found in nuclear, oil and gas, and petrochemical industries. Other types include inflatable seated butterfly valves used in dry bulk and slurry applications, and lined marine butterfly valves used in highly corrosive services. Each type of butterfly valve has features that make it the best fit for its intended application, offering reliable and efficient performance.

Preparing for Installation

Before installing a butterfly disc valve, it’s important to prepare thoroughly to ensure a successful and efficient installation process. First, make sure you have chosen the right type of valve for your specific application, considering factors such as fluid type, pressure, temperature, and flow rate. Once you have the correct valve, inspect it for any visible damage or defects that may have occurred during shipping or storage. Also, confirm that the valve’s size matches the pipe’s size where it will be installed. Preparing the installation site is equally important. Ensure that the pipeline is clean and free from any debris that could damage the valve or hinder its operation. If you’re replacing an old valve, properly dispose of it and clean the area where the new valve will be installed. If necessary, you might have to adjust the piping system to accommodate the new valve. Have all necessary tools and equipment on hand before starting the installation. These may include wrenches, flange spreaders, lubricants, gaskets, and bolts, among others. Always refer to the manufacturer’s instructions or a professional installer for specific installation procedures. Safety should be a top priority during the installation. Use appropriate personal protective equipment, and ensure the system is depressurized before starting the installation. By taking these steps, you can help ensure a smooth and safe installation process.

Tools and materials required for installation

The installation of a butterfly disc valve requires several specific tools and materials to ensure a successful and safe process. First, you’ll need the appropriate personal protective equipment (PPE) such as safety glasses, gloves, and possibly a hard hat, depending on the work environment. A set of wrenches or ratchet sets is necessary for tightening bolts and nuts. Flange spreaders may be needed to separate the flanges of the pipeline for valve placement. Lubricants are often required to ensure smooth operation of the valve and to prevent seizing of parts. Gaskets are crucial for creating a tight seal between the valve and pipe flanges, preventing leaks. Bolts and nuts are required to secure the valve in place between the flanges. Pipe supports or stands may also be necessary to hold the pipeline in place during installation. A measuring tape or ruler can be used to ensure the valve and pipe sizes match before installation. Lastly, it’s essential to have the manufacturer’s installation guide on hand for reference. This list could vary slightly based on the specific type of butterfly valve and the unique requirements of the installation site. It’s always best to refer to the manufacturer’s guidelines or consult with a professional installer for the most accurate information.

Safety measures to consider before starting the installation process

Safety should always be the top priority when installing a butterfly disc valve. Before starting the installation process, ensure that the system is completely depressurized and, if necessary, de-energized to prevent any accidental release of pressure or electrical shock. All personnel involved should wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hard hats, to protect against potential hazards. If you’re working in a confined space, make sure to follow all necessary protocols for safe entry, ventilation, and potential rescue operations. Check the installation area for any potential tripping hazards and clear these away before starting work. Always use tools and equipment in good condition and as they are intended to be used. Never force parts together; if something doesn’t fit, double-check your measurements and part specifications. Also, ensure that all personnel involved in the installation are adequately trained and understand the manufacturer’s instructions and safety guidelines. In case of any doubt or uncertainty, do not hesitate to consult with a professional installer or the valve manufacturer. By following these safety measures, you can minimize the risk of accidents and ensure a safe and successful installation process.

Step-by-step Guide to Butterfly Disc Valve Installation

Installing a butterfly disc valve involves a series of steps that must be followed carefully to ensure a successful and efficient installation. First, ensure all necessary safety precautions are in place, including wearing appropriate personal protective equipment (PPE) and ensuring the system is fully depressurized. Once safety measures are ensured, prepare the installation area by cleaning the pipeline where the valve will be installed. Remove any debris or remnants from the previous valve if you’re replacing one. Next, check the butterfly valve for any visible damages or defects. Confirm that the valve’s size matches the pipeline’s size.

Once the valve and pipeline are ready, align the valve between the flanges of the pipeline. Make sure the valve disc is in a partially open position to prevent damage during installation. Insert the gasket between the valve and flange surfaces, which helps to create a tight seal and prevent leaks. After positioning the valve correctly, insert the bolts through the flanges and tighten them using a wrench or ratchet set. Be careful not to over-tighten as this could cause damage to the flanges or gasket.

After the valve is secured in place, slowly open and close it to ensure it operates smoothly. If there’s any resistance or difficulty, recheck the installation. Finally, pressurize the system and check for any leaks. If there are no leaks and the valve operates smoothly, the installation process is complete.

Remember, this is a general guide and the specific steps might vary slightly based on the type of butterfly valve and the unique requirements of the installation site. Always refer to the manufacturer’s instructions or consult with a professional installer for the most accurate information.

Detailed steps on how to properly install a butterfly disc valve

Installing a butterfly disc valve involves careful attention to detail and a sequential process. First, ensure that all necessary safety precautions are in place. Use the appropriate personal protective equipment (PPE), and make sure that the system is fully depressurized and de-energized before beginning the installation.

The first step in the actual installation process is to clean the pipeline where the valve will be installed. Any debris or remnants from the previous valve (if it’s a replacement) should be removed to ensure a proper fit and seal.

Next, inspect the butterfly valve for any visible damages or defects. It’s crucial that the valve is in good condition before installation to prevent future issues. Also, verify that the valve’s size matches the pipeline’s size to ensure a proper fit.

Once the valve is ready to be installed, align it between the flanges of the pipeline. Make sure that the valve disc is in a partially open position during this step to prevent damage. Then, place a gasket between the valve and the flange surfaces. This creates a tight seal and helps prevent leaks.

After positioning the valve correctly, insert the bolts through the flanges and tighten them using a wrench or ratchet set. Be careful not to over-tighten, as this could cause damage to the flanges or the gasket.

Once the valve is secured, slowly open and close the valve to check its operation. If there’s any resistance or difficulty in operation, recheck your installation. Finally, pressurize the system and check for any leaks. If there are no leaks and the valve operates smoothly, the installation is successful.

Keep in mind that this is a general guide and the specific steps might vary based on the type of butterfly valve and the unique requirements of the installation site. Always refer to the manufacturer’s instructions or consult with a professional installer for the most accurate information.

Common mistakes to avoid during the installation process

When installing a butterfly disc valve, several common mistakes could lead to future problems if not avoided. One of the most frequent errors is neglecting to properly clean and prepare the pipeline before installation. Not ensuring the pipeline is fully depressurized and free from debris can result in an improper seal and potential leaks. Another common mistake is not verifying the sizing of the valve and the pipeline. Installing an ill-fitting valve can result in operational issues and may damage the pipeline over time.

Over-tightening the bolts during installation is another error that often occurs. While it’s important to secure the valve firmly, excessive force can potentially damage the flanges or the gasket, leading to leaks or even failure of the valve. Additionally, installing the valve with the disc in the fully closed position can cause damage to the disc during the installation process. It’s recommended to install the valve with the disc partially open.

Lastly, one major oversight is failing to test the valve after installation. Even if the valve appears to be installed correctly, testing its operation under pressure and checking for leaks is the only sure way to confirm its proper function. By being aware of these common mistakes, you can ensure a successful and efficient valve installation process.

Tips and tricks for a smooth installation process

To ensure a smooth installation process for a butterfly disc valve, there are several tips and tricks that can be helpful. First, always take the time to thoroughly read and understand the manufacturer’s instructions before you begin. These instructions often contain specific details and steps that are crucial for proper installation.

Ensure that you have all the necessary tools and materials ready before starting. This includes personal protective equipment, the correct size wrench or ratchet set, and any required gaskets or seals.

During the installation, remember to keep the valve disc in a partially open position. This reduces the risk of damaging the disc during the bolting process. Also, when tightening the bolts, use a star pattern (similar to changing a car tire) to ensure even pressure and avoid warping the flanges.

After the valve is installed, don’t forget to test its operation under pressure. Slowly open and close the valve to check for any resistance or issues. Also, inspect the valve and pipeline for any leaks. If a leak is detected, slightly tighten the bolts until the leak stops. However, be careful not to over-tighten as this could damage the flanges or gasket.

Lastly, remember that patience is key. Rushing through the installation process can lead to mistakes and problems down the line. Take your time, follow the steps carefully, and don’t hesitate to seek professional help if you’re unsure about any part of the installation.

Post-installation Checks

Once the installation of the butterfly disc valve is complete, it’s essential to conduct a series of post-installation checks to ensure that the valve operates correctly and safely. Begin by visually inspecting the valve and surrounding pipeline for any signs of physical damage, such as cracks, dents, or warping, which may have occurred during the installation process. Next, check the alignment of the valve within the pipeline to ensure it fits properly and is positioned correctly.

Following the visual inspection, it’s crucial to test the operational functionality of the valve under pressure. Slowly open and close the valve several times while monitoring its operation. The valve should operate smoothly without any resistance or unusual sounds. If there’s any grinding noise or stiffness, it might indicate an issue with the disc or the stem of the valve.

Moreover, it’s important to check for leaks around the valve body and along the pipeline. This can be done by applying a leak detection fluid or soap solution on the flanges and the pipe joints, and then looking for any bubbles that form. If a leak is detected, you may need to slightly tighten the bolts until the leak stops. However, avoid over-tightening as this could potentially damage the flanges or gasket.

Lastly, if your valve is equipped with a position indicator, verify that the indicator accurately reflects the valve’s open or closed status. A malfunctioning position indicator can lead to operational errors and potential safety risks.

Remember, these post-installation checks are not a one-time task – regular maintenance and checks should be carried out throughout the lifespan of the valve to ensure its ongoing performance and longevity. If at any point you encounter issues or uncertainties, don’t hesitate to consult with a professional or reach out to the manufacturer for guidance.

Procedures to ensure the butterfly disc valve has been installed correctly

To verify the correct installation of a butterfly disc valve, there are several procedures you should follow. Start by cross-checking the valve’s specifications with your system requirements to ensure it’s the right fit. After the valve is installed, perform a visual inspection to confirm proper alignment and secure attachment to the pipeline.

Next, test the valve’s operation by slowly opening and closing it while monitoring the movement of the disc. It should operate smoothly without any resistance or unusual noises. Additionally, check the valve’s positioning indicator (if it has one) to verify that it accurately represents the open or closed status of the valve.

A crucial part of the verification process is checking for leaks. Apply a leak detection fluid or soap solution on the flanges and pipe joints and look for any formation of bubbles which indicate a leak. If a leak is detected, slightly tighten the bolts until the leak stops, but avoid over-tightening as this could cause damage.

Lastly, conduct a pressure test to ensure the valve can handle the system’s operational pressure without failure. This involves closing the valve and increasing the pressure gradually while checking for any signs of distortion or leakage.

Remember, if you encounter any issues during these procedures, or if you’re uncertain about anything, consult with a professional or contact the valve manufacturer for guidance.

Initial operation and testing of the butterfly disc valve

The initial operation and testing of the butterfly disc valve are critical steps to ensure its proper functioning and integration into your system. Begin by slowly opening and closing the valve, paying close attention to any signs of resistance or abnormal noises that may indicate a problem with the disc or stem. The valve should operate smoothly and without difficulty.

Next, you’ll want to conduct a pressure test. This involves closing the valve and gradually increasing the system’s pressure to the valve’s maximum rated pressure. Monitor the valve and surrounding pipeline for any signs of distortion or leakage during this process.

Additionally, if your butterfly disc valve has a position indicator, make sure it accurately reflects the open or closed status of the valve during operation. Any discrepancy could lead to operational errors and potential safety risks.

Finally, check for any leaks around the valve body and along the pipeline. You can do this by applying a leak detection fluid or soap solution on the flanges and pipe joints, and then looking for bubbles that form, indicating a leak. If a leak is detected, slightly tighten the bolts until the leak stops, but be careful not to over-tighten as this could cause damage.

Remember, these initial operation and testing procedures are not a one-time event. Regular checks should be performed throughout the valve’s lifespan to ensure its continued performance and longevity. Always consult with a professional or the valve manufacturer if you encounter any issues or uncertainties during these procedures.

Butterfly Disc Valve Maintenance

Maintenance of the butterfly disc valve is crucial to ensure its efficient operation and longevity. A well-maintained valve can prevent system failures, reduce downtime, and save costs in the long run. Start with regular visual inspections to check for any signs of physical damage, such as cracks, dents, or warping, which could affect the valve’s performance. Also, pay attention to any rust, corrosion, or buildup on the disc that could hinder its movement.

Next, routinely test the valve’s functionality by slowly opening and closing it. The valve should operate smoothly without any resistance or abnormal sounds. If there’s any grinding noise or stiffness, it might indicate an issue with the disc or the stem of the valve that requires immediate attention.

Leaks are another important aspect to monitor during maintenance checks. Apply a leak detection fluid or soap solution on the flanges and pipe joints, and then look for any bubbles that form, indicating a leak. If a leak is detected, you may need to slightly tighten the bolts until the leak stops. However, avoid over-tightening as this could potentially damage the flanges or gasket.

If your butterfly disc valve has a position indicator, make sure it accurately reflects the valve’s open or closed status. A malfunctioning position indicator can lead to operational errors and potential safety risks.

Lastly, consider conducting periodic pressure tests to ensure the valve can handle the system’s operational pressure without failure. This involves closing the valve and gradually increasing the system’s pressure to the valve’s maximum rated pressure while monitoring for any signs of distortion or leakage.

Remember, maintenance should be an ongoing process, not a one-time event. Regular checks will help detect potential issues early and address them before they escalate into major problems. Always consult with a professional or the valve manufacturer if you encounter any issues or uncertainties during these procedures.

Importance of regular maintenance on the longevity and efficiency of the valve

Regular maintenance is vital for the longevity and efficiency of a butterfly disc valve. Over time, wear and tear, corrosion, or buildup can affect the valve’s performance, potentially leading to system failures or costly repairs. Regular inspections and maintenance can help detect these issues early, allowing for timely interventions that can extend the valve’s lifespan.

Maintenance tasks such as leak checks, pressure tests, and functional checks ensure that the valve operates at its peak efficiency. For instance, identifying leaks early can prevent loss of fluid or gas, ensuring optimal system performance and reducing waste. Similarly, regular functionality checks can ensure the valve opens and closes smoothly, reducing the risk of operational errors or potential safety hazards.

Moreover, regular maintenance can help maintain the valve’s seal integrity, preventing leaks and ensuring the valve can handle the system’s operational pressure. This not only contributes to the valve’s longevity but also to the overall efficiency of the system it’s part of.

In conclusion, regular maintenance is a small investment that can yield significant returns in terms of improved valve efficiency, increased lifespan, reduced downtime, and cost savings.

Maintenance procedures and schedule

Establishing a maintenance schedule and following proper procedures are key to ensuring the longevity and performance of your butterfly disc valve. While the exact frequency of maintenance can depend on the specific application and operating conditions, a general rule is to perform a basic inspection every six months, with more comprehensive maintenance annually.

During the biannual check, visually inspect the valve for any signs of physical damage or wear, such as cracks, dents, rust, or buildup on the disc. Test the valve’s functionality by opening and closing it to ensure smooth operation without resistance or abnormal sounds.

The annual maintenance should be more thorough and include all the steps of the biannual check, plus additional tasks. Conduct a pressure test to ensure the valve can handle the system’s operational pressure. Check for leaks around the valve body, flanges, and pipe joints using a leak detection fluid or soap solution. If the valve has a position indicator, verify its accuracy.

Remember to document each maintenance session, including the date, tasks performed, and any issues detected and actions taken. This documentation can be helpful in identifying recurring issues or patterns that could indicate a larger problem. Always consult with a professional or the valve manufacturer if you encounter any issues or uncertainties during these procedures.

When to repair vs. when to replace a butterfly disc valve

Deciding whether to repair or replace a butterfly disc valve depends on several factors. If the valve is relatively new and the issue is minor, such as a small leak or slight stiffness in operation, it may be more cost-effective to repair it. Professional servicing can often resolve these issues, and the valve can continue to function efficiently for many more years.

However, if the valve is old and has frequent problems despite regular maintenance, it might be time to consider replacement. Recurring issues could indicate underlying problems that repairs might not fully address. Similarly, if the valve has significant physical damage, such as large cracks, severe corrosion, or extensive wear and tear, replacing it might be the safer and more economical option in the long run.

Also, consider the cost implications. If the cost of repair, including parts and labor, is close to or exceeds the cost of a new valve, replacement might be the better choice. Always consult with a professional or the valve manufacturer when making these decisions to ensure you’re taking the most effective and efficient course of action.

Troubleshooting Common Butterfly Disc Valve Problems

Butterfly disc valves are typically robust and reliable, but like any mechanical component, they can develop issues over time. Understanding common problems and how to troubleshoot them can save time and money, and prevent potential system failures.

Stiff Operation: If the valve is difficult to open or close, it could be due to a buildup of debris or corrosion in the mechanism. Regular cleaning and lubrication can often resolve this issue. However, if the problem persists, it might indicate more serious internal damage requiring professional attention.

Leakage: Leaks can occur around the valve stem or between the valve body and the pipe flanges. Check for signs of leakage during regular inspections. If a leak is detected, try tightening the bolts. If this doesn’t stop the leak, the seal or gasket may need to be replaced. Remember, prolonged leakage can lead to corrosion and further damage, so address this issue promptly.

Inefficient Performance: If the valve isn’t performing as efficiently as it should, it could be due to wear and tear on the disc or seat. Over time, these components can wear down, affecting the valve’s sealing ability and overall performance. In such cases, these parts may need to be replaced.

Faulty Position Indicator: Some butterfly disc valves have a position indicator that shows whether the valve is open or closed. If the indicator isn’t accurate, it could lead to operational errors. Check the indicator during each maintenance session and recalibrate or replace it if necessary.

Unusual Noises: If you hear unusual noises when operating the valve, such as grinding or squeaking, it could indicate a lack of lubrication or a misaligned disc. Lubricate the valve regularly to ensure smooth operation, and check the disc alignment during maintenance sessions.

Remember, always consult with a professional or the valve manufacturer if you encounter persistent or serious issues. While troubleshooting can resolve minor problems, some issues will require expert attention to ensure the valve’s longevity and efficiency.

Common issues that may arise with butterfly disc valves

Butterfly disc valves, like all mechanical components, can encounter several common issues over time. One of the most typical problems is leakage, which can occur due to worn or damaged seals or gaskets. This could lead to fluid loss, system inefficiency, and potential damage to other parts of the system. Another common issue is stiff operation or difficulty in turning the valve. This could be due to a buildup of debris, rust, or lack of lubrication, affecting the smooth movement of the disc. Over time, wear and tear on the disc or valve seat can also affect the valve’s performance, leading to inefficient sealing and flow control. Lastly, if the valve features a position indicator, inaccuracies in its readings can lead to operational errors. Regular maintenance and inspections can help identify and address these issues early, ensuring the longevity and efficiency of your butterfly disc valve.

Steps to diagnose and rectify these problems

Diagnosing and rectifying problems with butterfly disc valves involves several steps. Start with a visual inspection of the valve, looking for signs of leakage, corrosion, or physical damage. For leaks, check around the valve stem and the pipe flanges. If you find a leak, try tightening the bolts. If the leak persists, the seal or gasket may need replacement. For stiff operation, check for debris or rust that might be hindering the movement of the disc. Clean and lubricate the valve to see if this resolves the issue. If not, a more serious internal issue may be present, requiring professional attention.

For issues with valve performance, inspect the disc and seat for wear and tear. If they appear worn, they may need to be replaced. If your valve has a position indicator and it’s giving inaccurate readings, check if it needs recalibration. If recalibration doesn’t solve the problem, the indicator may need to be replaced.

Remember, while these steps can help identify and resolve common issues, always consult with a professional or the valve manufacturer for persistent or serious problems. Regular maintenance and inspections are key to maintaining the efficiency and longevity of your butterfly disc valve.

When professional help is needed for troubleshooting

While basic troubleshooting and maintenance of butterfly disc valves can often be performed by the user, there are certain situations where professional help is necessary. If the valve continues to leak despite attempts to tighten bolts or replace seals, it could indicate a more serious issue that requires expert attention. Similarly, if the valve remains stiff to operate even after cleaning and lubrication, it might suggest internal damage or misalignment that needs professional rectification. If the valve’s performance doesn’t improve despite replacing worn components, it could be due to complex mechanical issues beyond the scope of basic troubleshooting. Additionally, if the position indicator continues to give inaccurate readings after attempted recalibration, it may require expert repair or replacement. In all these scenarios, it’s crucial to seek professional assistance rather than attempting further DIY fixes, as incorrect handling could potentially worsen the problem and lead to more significant system issues.

Conclusion

In conclusion, butterfly disc valves are vital components in many fluid control systems, playing a critical role in regulating flow and maintaining system efficiency. However, like all mechanical components, they are subject to wear and tear, and can develop issues over time. Understanding the common problems and their symptoms is the first step in effective valve maintenance.

Leaks, stiff operation, worn-out components, and inaccurate position indicators are all signs that your valve may need attention. Regular visual inspections can help detect these issues early on, and simple steps such as tightening bolts, cleaning and lubricating the valve, replacing worn parts, and recalibrating indicators can often resolve them.

However, it’s important to remember that not all issues can or should be handled in-house. If a problem persists despite your best efforts, or if you suspect internal damage or complex mechanical issues, it’s essential to seek professional help. Incorrect handling can exacerbate the problem and potentially lead to more serious system issues.

Valve maintenance isn’t just about fixing problems as they arise – it’s about preventative care. Regular maintenance and inspections can extend the life of your butterfly disc valve, improve system efficiency, and reduce the likelihood of unexpected breakdowns. This guide is intended to provide you with a solid foundation for understanding, installing, and maintaining butterfly disc valves, but remember that every system is unique. Always consult with professionals or your valve manufacturer for advice tailored to your specific circumstances.

With proper care and maintenance, your butterfly disc valves can provide reliable service for many years. Embrace the process as an integral part of your operations, and you’ll reap the rewards in terms of improved performance and reduced downtime.

Recap of the importance of proper installation and maintenance of butterfly disc valves

In recap, the importance of proper installation and maintenance of butterfly disc valves cannot be overstated. These valves are integral components in many fluid control systems, responsible for regulating flow and ensuring system efficiency. Incorrect installation can lead to immediate problems like leaks or operational difficulties, and over time, it can result in premature wear and tear. Proper maintenance, on the other hand, not only helps in identifying and rectifying common issues such as leaks, stiff operation, and worn-out parts but also extends the lifespan of the valve. Regular inspections, timely replacement of worn components, and professional help when needed are all part of effective valve maintenance. Ultimately, investing time and effort in correct installation and ongoing maintenance of butterfly disc valves significantly enhances system performance and reduces the likelihood of unexpected breakdowns.

Final thoughts on how proper maintenance can save time, money, and ensure safety

Final thoughts on this matter underline that proper maintenance of butterfly disc valves is not just a matter of operational efficiency, but also of time, money, and safety. Regular and thorough maintenance can help identify potential issues before they become significant problems, saving time that would otherwise be spent on troubleshooting and repairs. Moreover, by extending the lifespan of the valves, maintenance reduces the need for costly replacements. It’s not just about the financial aspect; well-maintained valves are less likely to fail unexpectedly, which could potentially lead to hazardous situations depending on the nature of the fluid being controlled. Therefore, by ensuring your butterfly disc valves are properly maintained, you’re not just improving performance and saving money, but also contributing to a safer working environment.