Description

High Performance Butterfly Valve Lug Series

The Lug Series High Performance Butterfly Valves is designed to excel in high-pressure applications, providing a cost-effective solution for industry professionals requiring bubble-tight shut-off. Engineered with an eccentric disc and offset shaft, this valve incorporates a flexible-lip sealing system within a lightweight, compact body. The resulting superior performance, durability, and ease of operation set it apart from other valves in the market.

Advanced Design & Materials

The Lug Series valve boasts several key design features that contribute to enhanced performance and durability:

- One-piece stem design with ISO 5211 square drive: Ensures optimal valve control and excellent torque transmission.

- ISO 5211 direct mounting flange on the valve body: Allows for seamless actuator integration, simplifying actuator mounting and reducing installation time.

- Double offset disc: Reduces valve torque, leading to smooth and efficient operation.

- Extended neck for pipe insulation: Accommodates temperature fluctuations and protects the stem seal, extending the valve’s service life.

The valve’s construction uses high-quality materials to ensure strength, reliability, and longevity. These materials include:

- Multiply rows of RPTFE chevron for soft seat valve: Provides resilient sealing and enhanced resistance to wear and tear.

- Graphite chevron for fire safe and metallic seat: Ensures superior sealing performance, even under high-temperature, high-pressure conditions.

Easy Installation & Maintenance

The Lug Series valve incorporates numerous features that make it easy to install, maintain, and operate, saving both time and resources. Notable features include:

- Easy-adjust gland packing: Accessible even with the actuator mounted in place, allowing for convenient adjustment and reduced downtime.

- Belleville washers on the gland nut: Offer reliable primary sealing between shaft and packing, ensuring tight shut-off and reduced maintenance.

- Retaining ring: Serves as both stem blowout proof and ensures even pressure on packing, enhancing sealing performance.

- Pin-less shaft to disc connection: Makes valve assembly and parts replacement convenient and reliable, even in corrosive environments.

- Seat retainer: Supports the seat, allowing for easy changeout, reducing maintenance efforts.

Compatibility & Efficiency

This Lug High Performance Butterfly Valve is designed with compatibility in mind, incorporating features such as:

- ISO 5211 square drive and direct mounting flange: Facilitate easy pairing with pneumatic actuators, simplifying installation and ensuring compatibility with various actuator types.

- Self-energized seat: Prolongs service life and minimizes maintenance requirements, increasing cost efficiency.

In summary, the Lug Series High Performance Butterfly Valve is an ideal choice for professionals seeking optimal performance in high-pressure applications, thanks to its advanced design, quality materials, ease of operation, and compatibility options. Offering numerous advantages over competing valves, this valve’s superior sealing capabilities, durability, and efficiency make it a smart investment for your industrial needs.

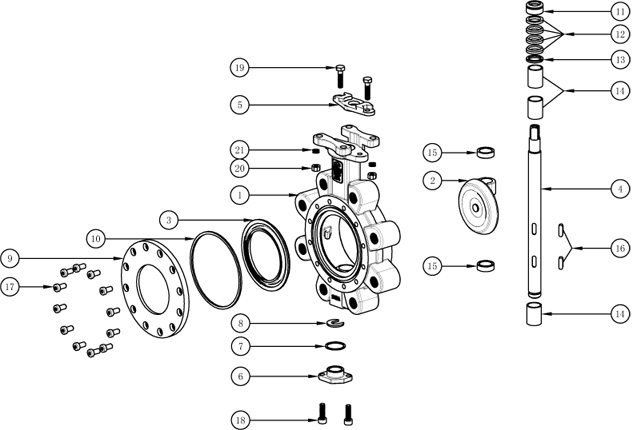

PARTS LIST AND MATERIAL SPECIFICATION

| No. | Part name | Material | |

| 1 | Body | WCB | CF8M |

| 2 | Disc | CF8* | CF8M* |

| 3 | Seat | RPTFE,SS316+RPTFE,SS316 | |

| 4 | Shaft | 17-4 PHSS,1.4462 | |

| 5 | Packing gland | CF8 | |

| 6 | Bottom cover | Same as body | |

| 7 | Cover seal | Graphite | |

| 8 | Thrust washer | SS316 | |

| 9 | Seat retainer | WCB | CF8M |

| 10 | Gasket | RPTFE, Graphite | |

| 11 | Retaining ring | SS304 | |

| 12 | Packing | RPTFE, Graphite | |

| 13 | Packing ring | SS316 | |

| 14 | Bearing | SS316+PTFE | |

| 15 | Thrust bearing | SS316 | |

| 16 | Key | SS316 | |

| 17 | Bolt | SS316 | |

| 18 | Bolt | SS304 | |

| 19 | Bolt | SS304 | |

| 20 | Nut | SS304 | |

| 21 | Belleville washer | SS304 | |

| *Supersonic spray welding of different materials on sealing surface of metal seating valve according to requirements | |||

TECHNICAL DATA

| Connection | Lug |

| Size | 3″-24″ |

| Pressure | Class150,Class300 |

| Flange standard | ASME B16.5 Class150,Class300; EN1092 PN16, PN25, PN40 |

| Face to face | API 609 Category B valve Wafer |

| Pressure test | API 598 |

| Temperature | PTFE seat -29°C to +200°C,metal seat -29°C to +400°C |

| Operator | Lever,Gear box,Pneumatic actuator,Electric actuator |

CLASS 150LB

| SIZE | A | B | C | D | D1 | E | Top Flange | G | L | WT(kg) | |

| DN | INCH | Class150 | |||||||||

| 50 | 2″ | 126 | 79 | 13.5 | 92 | 123 | 11 | F05 | 45 | 43 | 5 |

| 65 | 2 1/2″ | 126 | 87 | 13.5 | 105 | 150 | 11 | F05 | 45 | 46 | 6 |

| 80 | 3″ | 145 | 100 | 17.5 | 130 | 156 | 11 | F07 | 72 | 48 | 8 |

| 100 | 4″ | 170 | 124 | 17.5 | 157 | 218 | 14 | F07 | 91 | 54 | 10 |

| 125 | 5″ | 185 | 144 | 17.5 | 186 | 241 | 14 | F07 | 114 | 57 | 15 |

| 150 | 6″ | 203 | 150 | 18.5 | 216 | 264 | 17 | F10 | 145 | 57 | 20 |

| 200 | 8″ | 239 | 186 | 24.5 | 269 | 325 | 22 | F10 | 192 | 64 | 23 |

| 250 | 10″ | 275 | 226 | 24.5 | 324 | 394 | 22 | F10 | 240 | 71 | 42 |

| 300 | 12″ | 307 | 251 | 30 | 380 | 471 | 27 | F12 | 285 | 81 | 60 |

| 350 | 14″ | 337 | 294 | 30 | 416 | 520 | 27 | F12 | 328 | 92 | 100 |

| 400 | 16″ | 368 | 320 | 30 | 476 | 585 | 27 | F14 | 373 | 102 | 155 |

| 450 | 18″ | 406 | 341 | 39 | 534 | 625 | 36 | F16 | 422 | 114 | 200 |

| 500 | 20″ | 442 | 383 | 49 | 588 | 693 | 46 | F16 | 470 | 127 | 270 |

| 600 | 24″ | 493 | 442 | 49 | 692 | 807 | 46 | F25 | 570 | 154 | 420 |

CLASS 300LB

| SIZE | A | B | C | D | D1 | E | Top Flange | G | L | WT(kg) | |

| DN | INCH | Class300 | |||||||||

| 50 | 2″ | 126 | 79 | 13.5 | 92 | 155 | 11 | F05 | 45 | 43 | 6 |

| 65 | 2 1/2″ | 126 | 87 | 13.5 | 105 | 178 | 11 | F05 | 45 | 46 | 7 |

| 80 | 3″ | 145 | 100 | 17.5 | 130 | 199 | 11 | F07 | 72 | 48 | 10 |

| 100 | 4″ | 170 | 124 | 17.5 | 157 | 243 | 14 | F07 | 91 | 54 | 12 |

| 125 | 5″ | 185 | 144 | 17.5 | 186 | 265 | 14 | F07 | 114 | 57 | 18 |

| 150 | 6″ | 203 | 150 | 18.5 | 216 | 312 | 17 | F10 | 145 | 57 | 25 |

| 200 | 8″ | 257 | 204 | 24.5 | 269 | 370 | 22 | F10 | 192 | 73 | 40 |

| 250 | 10″ | 288 | 238 | 30 | 324 | 438 | 27 | F12 | 240 | 83 | 65 |

| 300 | 12″ | 330 | 268 | 30 | 380 | 512 | 27 | F12 | 285 | 92 | 100 |

| 350 | 14″ | 337 | 294 | 39 | 416 | 579 | 36 | F14 | 320 | 117 | 200 |

| 400 | 16″ | 368 | 320 | 49 | 476 | 643 | 46 | F16 | 363 | 133 | 260 |

| 450 | 18″ | 406 | 341 | 49 | 534 | 705 | 46 | F16 | 400 | 149 | 380 |

| 500 | 20″ | 442 | 383 | 49 | 588 | 769 | 46 | F25 | 450 | 159 | 470 |

| 600 | 24″ | 500 | 442 | 58 | 692 | 908 | 55 | F25 | 550 | 181 | 780 |

FAQs

What is a high performance butterfly valve?

A High Performance Butterfly Valve is a pivotal device in advanced flow control systems, meticulously designed to operate with unyielding precision and robustness under high-pressure and high-temperature scenarios. Embodying the pinnacle of valve manufacturing innovation, these valves are distinguished by their durability and versatility, capable of excelling in on/off and throttling service applications across a diverse array of industries.

Constructed using premium materials that adhere to industry-specific certifications, our High Performance Butterfly Valves feature a disc mechanism which pivots on a sturdy stem, allowing for swift and secure flow regulation. The precision-engineered disc optimizes flow characteristics and minimizes pressure drops, delivering a performance that commands respect within the sector.

Can a high performance butterfly valve handle high pressures and temperatures?

High Performance Butterfly Valves are quintessential for industries requiring control mechanisms that can endure the rigors of high pressures and temperatures. Our valves are precision-engineered to operate reliably within an extensive range of demanding conditions, asserting their dominance in the market as the preferred solution for severe service applications.

Are there any industry standards or certifications for high performance butterfly valves?

In the sphere of high performance butterfly valve manufacturing, adherence to industry standards and possessing authoritative certifications is not merely a matter of compliance, but a testament to our unwavering dedication to quality, safety, and performance. Our products are meticulously crafted to meet, if not surpass, the rigorous benchmarks set forth by esteemed institutions and standardization bodies.

The American Water Works Association (AWWA) C519-18 High-Performance Waterworks Butterfly Valve Standard establishes the minimum requisites for high-performance butterfly valves ranging in size from 3 inches (75 mm) to 60 inches (1,500 mm), delineating the criteria for myriad body constructions and materials to ensure optimal functionality within waterworks systems

Our commitment to excellence is also reflected through our compliance with the American Bureau of Shipping (ABS), where our valves are rigorously assessed to certify their reliability in maritime applications

Furthermore, we uphold internationally recognized standards such as ISO 9001, signifying our allegiance to quality management systems, and ISO 14001, underscoring our pledge to environmental stewardship

In the echelons of high-stake industries such as petrochemicals and natural gas, our products are deemed API 607 Fire Safe